It is an aromatic organic compound with the molecular formula C6H5NH2. It is a colorless, toxic oily liquid that is soluble in water and has a sweet smell similar to ammonia. Aniline was first isolated from the dye indigo in 1826 and has played an integral role in the development of the chemical industry ever since.

It is industrially produced by the catalytic reduction of nitrobenzene. Nitrobenzene is produced by the nitration of benzene using a mixture of concentrated nitric and sulfuric acid as the nitrating agent. Nitrobenzene is then reduced to it, usually by hydrogenation over an iron or zinc catalyst.

Get more insights: Aniline (https://articlescad.com/a-...

#CoherentMarketInsights #Aniline #MethyleneDiphenylDiisocyanate #Insulation #RubberProducts #ConsumerGoods #automotive #packaging

Commercially, it is prepared by two different processes - reduction of nitrobenzene and catalytic ammoxidation of benzene. Nitrobenzene provides about 90% of world's supply. It is reduced to aniline by hydrogenation over metal catalysts such as Raney nickel or iron. The most common industrial process involves ammoxidation of benzene to produce cyclohexylamine which is then dehydrogenated to aniline.

Get More Insights On Aniline

https://www.insightprobing...

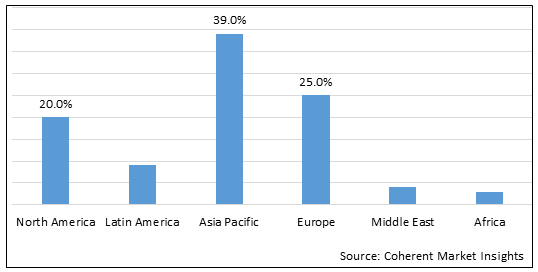

Aniline is produced by two main routes. In the most common process, benzene is nitrated to nitrobenzene, followed by hydrogenation to aniline. Another process involves hydrogenating toluene to produce methyl aniline followed by removal of the methyl group to yield aniline. The global production capacity of aniline is over 4 million metric tons per year. Major producers are China, India, Taiwan, South Korea and Western Europe.

Aniline - https://www.coherentmarket...

Aniline Market Trends, Size, Share, Trends & Insights 2031

Aniline Market size is estimated to be valued at US$ 7.8 Mn Tons in 2024 and is expected to expand at a CAGR of 5.4%, reach US$ 11.3 Mn Tons by 2031.

https://www.coherentmarketinsights.com/market-insight/aniline-market-4378The Nitrobenzene Market is estimated to be valued at US$ 12.84 billion in 2025 and is expected to exhibit a CAGR of 5.7% over the forecast period.

The nitrobenzene market comprises aromatic chemicals that find extensive applications across numerous industries. Nitrobenzene acts as an important intermediate for the production of aniline, which is further used to manufacture polyurethanes, synthetic rubber, pesticides, and nylon. The explosive growth of the automotive and construction industries has driven the demand for polyurethane foams and coatings, thereby augmenting the sales of nitrobenzene substantially.

Nitrobenzene Market- https://logcla.com/blogs/5...

#CoherentMarketInsights #NitrobenzeneChem #NitrobenzeneMarket #Nitrobenzene #NitrobenzeneMarketShare

Nitrobenzene Market is Estimated to Witness High Growth due to...

The nitrobenzene market is a crucial part of the chemical industry owing to its diverse range of applications. Nitrobenzene is an organic compound which possesses significant advantages like solvent properties, high boiling point, and ability to undergo substitution reactions. It finds major uses...

https://logcla.com/blogs/505924/Nitrobenzene-Market-is-Estimated-to-Witness-High-Growth-due-toCommercially, it is prepared by two different processes - reduction of nitrobenzene and catalytic ammoxidation of benzene. Nitrobenzene provides about 90% of world's supply. It is reduced to aniline by hydrogenation over metal catalysts such as Raney nickel or iron. The most common industrial process involves ammoxidation of benzene to produce cyclohexylamine which is then dehydrogenated to aniline.

Get More Insights On Aniline

https://www.insightprobing...

Explore More The Report:Sterile Injectables Market

https://www.reddit.com/r/Z...

Commercially, it is prepared by two different processes - reduction of nitrobenzene and catalytic ammoxidation of benzene. Nitrobenzene provides about 90% of world's supply. It is reduced to aniline by hydrogenation over metal catalysts such as Raney nickel or iron. The most common industrial process involves ammoxidation of benzene to produce cyclohexylamine which is then dehydrogenated to aniline.

Get More Insights On Aniline

https://www.insightprobing...

Explore More The Report:Sterile Injectables Market

https://www.reddit.com/r/Z...

Commercially, it is prepared by two different processes - reduction of nitrobenzene and catalytic ammoxidation of benzene. Nitrobenzene provides about 90% of world's supply. It is reduced to aniline by hydrogenation over metal catalysts such as Raney nickel or iron. The most common industrial process involves ammoxidation of benzene to produce cyclohexylamine which is then dehydrogenated to aniline.

Get More Insights On Aniline

https://www.insightprobing...

Explore More The Report:Sterile Injectables Market

https://www.reddit.com/r/Z...

Dwngo social network website

Dwngo – The Social Media Platform! * Share your thoughts & ideas * Publish blogs & trending stories * Connect, engage & grow your networkJoin now & be part of the future of social networking! #SocialMedia #Blogging #Dwngo --https://dwngo.com/