https://www.maximizemarket...

Powder Metallurgy Components Market – Global Industry Analysis

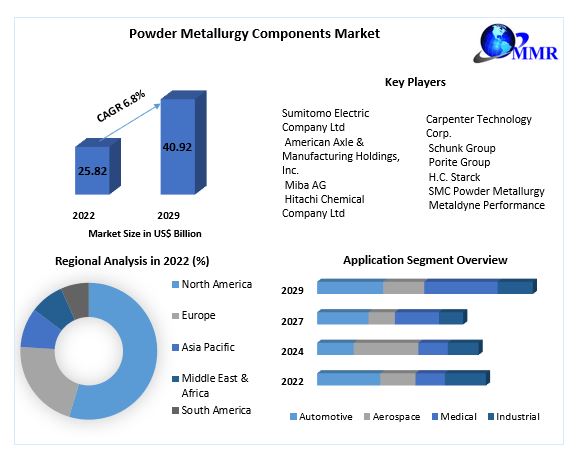

Powder Metallurgy Components Market was valued at US$ 25.82 Bn. in 2022, and is expected to reach US$ 40.92 Bn. by 2029, at a CAGR of 6.8 %

https://www.maximizemarketresearch.com/market-report/global-powder-metallurgy-components-market/25524/The Elemental Fluorine Market has been experiencing steady growth due to its extensive applications in various industries such as electronics, pharmaceuticals, metallurgy, and nuclear fuel processing. Elemental fluorine is a highly reactive and corrosive gas used in a range of industrial processes, making it a critical component in manufacturing and scientific research. With the increasing demand for high-performance materials and advancements in fluorine-based technologies, the Elemental Fluorine Market Size is expected to expand significantly in the coming years.

https://wemarketresearch.c...

Elemental Fluorine Market Analysis | Size, Forecasts, and Insights

Explore the latest trends in Elemental Fluorine market. Discover comprehensive insights on demand, applications, Segmentation, Regional Outlook and competitive landscape.

https://wemarketresearch.com/reports/elemental-fluorine-market/1536High-temperature furnaces play a crucial role in heat treatment, material testing, and research applications. These furnaces provide a controlled environment for precise thermal processing, ensuring uniform heat distribution. A muffle furnace is widely used in laboratories and industries for ashing, calcination, and ceramics firing. Its enclosed heating system prevents direct flame contact, making it ideal for accurate and contamination-free results. Industries like metallurgy, pharmaceuticals, and material science rely on its efficiency. When choosing a muffle furnace, consider temperature range, insulation quality, and chamber capacity. Understanding its working mechanism helps ensure precise and reliable high-temperature testing outcomes.

read more - https://www.testing-instru...

Need a reliable muffle furnace? Call +91-9210903903 for expert guidance.

The global Spherical Metal Powder Market is poised for impressive growth, projected to reach USD 10.2 billion by 2032, up from USD 5.3 billion in 2023, according to the latest study by DataIntelo. The market is expected to register a strong CAGR of 7.5% during the forecast period, driven by rapid adoption across 3D printing, aerospace, and medical industries.

Spherical metal powders are highly sought-after for their superior flowability, uniform packing density, and optimal thermal conductivity. These properties make them ideal for advanced manufacturing processes, including metal injection molding, powder metallurgy, and laser sintering.

Enquiry Before Buying of Spherical Metal Powder Market Report | Global Forecast From 2025 To 2033

In 2023, the global market size for spherical metal powder was valued at approximately USD 1.5 billion.

https://dataintelo.com/enquiry-before-buying/264112Read more: https://wemarketresearch.c...

#HeatTreating #ThermalProcessing #MetalHeatTreatment #IndustrialFurnaces #HeatTreatingIndustry #ManufacturingTech #MaterialsEngineering #Hardening #Tempering #Annealing #HeatTreatmentSolutions #Metallurgy #SurfaceEngineering

Heat Treating Market Size, Growth, Trends & Forecast to 2035

The Heat Treating Market is set to grow at a 3.4% CAGR, reaching USD 145.38B by 2035 from USD 114.23B in 2025, following an average growth trend.

https://wemarketresearch.com/reports/heat-treating-market/1656A muffle furnace is a high-temperature laboratory oven used to perform controlled heating of materials in a clean, insulated environment. It consists of a heating chamber enclosed by insulation, which isolates the contents from direct flame or combustion byproducts. This design ensures precise, contamination-free heating for applications requiring uniform temperature.

Commonly used in laboratories, metallurgy, ceramics, and material testing industries, muffle furnaces can reach temperatures up to 1800°C. They are ideal for ashing, sintering, annealing, and heat treatment processes. With programmable temperature control, safety features, and durable construction, modern muffle furnaces offer efficient, repeatable performance for quality analysis and research. Contact us at +91 9210 903 903 or infoprestogroup.com for premium quality testing instruments tailored to your needs.

For More Information Visit our website:- https://www.prestogroup.co...

This shift from analog to digital has led to increased adoption across diverse industries, including electronics, healthcare, metallurgy, education, and life sciences. At the forefront of this transformation are innovative digital microscope manufacturers who are constantly redefining performance standards through advanced design, automation, and integration.

visit: https://differ.blog/p/top-...

Read More: https://wemarketresearch.c...

#Molybdenum #Mo42 #RareMetal #TransitionMetal #MolybdenumSteel #MolybdenumAlloy #Metallurgy #HighStrengthMetal #HeatResistantMetal

Enhance metal strength and density with infiltration powder metallurgy. MIM Supplier offers advanced solutions for producing high-performance, precision-engineered metal parts. For more details, please visit :- https://mim-supplier.com/b...

What is Infiltration Powder Metallurgy – MIM Supplier

Infiltration powder metallurgy (IPs) are typically copper-based materials mixed or alloyed with other metals. Full body parts can be easily plated, welded or under-welded and can improve machinability.First, let me show you that the powder metallurgy process is a series of graphic steps : Mixing of ..

https://mim-supplier.com/blogs/knowledge/what-is-infiltration-powder-metallurgyA muffle furnace is a high-temperature heating device commonly used in laboratories and industrial settings for applications such as ashing, sintering, heat treatment, and material testing. It operates by enclosing the sample in a chamber heated by electric coils, keeping the material isolated from combustion by-products or direct flame. This ensures uniform heating and precise temperature control, often reaching up to 1200°C or higher. Muffle furnaces are essential in research labs, ceramics production, metallurgy, and quality assurance, offering reliability, efficiency, and consistent results for high-temperature processing tasks. Contact us at +91 9210 903 903 or infoprestogroup.com for premium quality testing instruments tailored to your needs.

For more information visit our website:- https://www.prestogroup.co...

Looking for a reliable Muffle Furnace? Our advanced furnace ensures precise temperature control for material testing, ashing, and heat treatment applications. Built with high-grade insulation and durable construction, it delivers efficient performance in laboratories and industrial settings. Designed for uniform heating, it operates at high temperatures with excellent energy efficiency. Ideal for research, metallurgy, and quality control, our Muffle Furnace guarantees accuracy and consistency. Choose from a range of models to suit your testing needs. Order now to enhance your laboratory’s efficiency with a trusted Muffle Furnace solution.

Visit Website:- https://www.testing-instru...

Visit Address:- I-42, DLF Industrial Area, Phase-1,

Delhi Mathura Road,

Faridabad-121003, Haryana, India.

The muffle furnace is a versatile laboratory instrument used for high-temperature applications, including ashing, heat treatment, and material testing. It provides uniform heating in a controlled environment, ensuring precise results across various industries like ceramics, metallurgy, and pharmaceuticals. The furnace's insulated chamber minimizes heat loss, making it energy-efficient and reliable for prolonged use. Essential for processes requiring temperatures up to 1200°C or more, it aids in research, production, and quality assurance. Designed for durability and safety, the muffle furnace is a vital tool for laboratories and manufacturing units requiring consistent high-temperature operations.

Visit - https://www.testing-instru...

Inorganic materials have thus far underpinned large-scale industrialization globally. However, sustainable production and consumption hold the key to ensuring these vital resources meet future societal needs in an environmentally responsible manner. Innovation remains the driving force to realize that goal.

This includes minerals acids like sulfuric acid and hydrochloric acid. Important bases include sodium hydroxide, potassium hydroxide and calcium hydroxide. These find wide uses in chemical processes, metallurgy, water treatment, etc.

Inorganic Chemicals- https://prachicmi.liveposi...

#CoherentMarketInsights #ChemicalCompounds #ElementsMatter #MineralsAndMetals #NonOrganicScience

Inorganic Chemicals: Substances that Shape our Daily Lives

Classification of Inorganic Chemicals Inorganic chemicals can be broadly classified into various categories based on their chemical structure and composition.

https://prachicmi.livepositively.com/inorganic-chemicals-substances-that-shape-our-daily-lives/new=1This area of research is applicable to powder metallurgy in water manufacture. It develops high-performance components that are inexpensive and lightweight; that is, it achieves high efficiency by producing advanced powder processes in metal form. For more details, please visit :- https://mimsupplierus.word...

Powder Metallurgy in Automotive Applications: Revolutionizing Vehicle Manufacturing – XY Electronics Technology Co., Ltd

This area of research is applicable to powder metallurgy in water manufacture. It develops high-performance components that are inexpensive and lightweight; that is, it achieves high efficiency by producing advanced powder processes in metal form. Metal powder is preferably made through consolidatio..

https://mimsupplierus.wordpress.com/2025/04/30/powder-metallurgy-in-automotive-applications-revolutionizing-vehicle-manufacturing/At XY Electronics Technology Co., Ltd, the 5 Applications of Powder Metallurgy include automotive components, electrical contacts, medical implants, industrial tools, and consumer electronics, ensuring high precision, durability, and cost-effective production for advanced industries. For more details, please visit :- https://mim-supplier.com/b...

Practical Application of Blending in Powder Metallurgy – MIM Supplier

Blending in Powder MetallurgyPowder metallurgy is of great importance in the reproduction and processing of substances with high melting points such as refractory metals. This is because these metals are difficult to produce by other means such as casting and melting. Examples of refractory metals a..

https://mim-supplier.com/blogs/knowledge/practical-application-of-blending-in-powder-metallurgy