Printing Machine Market is Expected to Witness High Growth Owing to Rising Demand from Packaging Industry

The printing machine market involves a wide range of equipment used for various printing applications including flexography, offset lithography, gravure, screen, and digital printing. Printing machines are used across industries such as packaging, publication, labels and cards, textiles, and ceramics to print content on surfaces like paper, plastic, metal, glass, fabric, etc. The demand for printing machines is driven by the need for product labeling & branding, publication of books, newspapers & periodicals, and decoration of various surfaces. The advantages of printing machines include high production rates, versatility in printing various materials, consistent and repeatable results, and economic volumes for short & medium runs.

The Global printing machine market is estimated to be valued at US$ 47.6 billion in 2024 and is expected to exhibit a CAGR of 5.9% over the forecast period 2024 To 2031.

Key Takeaways

Key players operating in the printing machine market are Heidelberg Printing Machines AG, Koenig & Bauer AG, Bobst Group SA, KOMORI Corporation, and Rotatek S.A.

The packaging industry has been adopting flexible and digital printing to improve aesthetics and provide product information which is opening growth opportunities for printing machine manufacturers.

The Printing Machine Market Size is witnessing expansion in Asia Pacific and Middle East & Africa region due to growth of publishing, textile, and packaging industries in developing countries.

Market drivers

Rising demand from the packaging industry is a major factor contributing to the growth of the printing machine market. Growth in the e-commerce sector has increased the demand for customized and short run package printing which is driving the installation of digital & flexographic printing presses. The need for product identification and branding through labels and packaging is also positively impacting the market.

P

The printing machine market involves a wide range of equipment used for various printing applications including flexography, offset lithography, gravure, screen, and digital printing. Printing machines are used across industries such as packaging, publication, labels and cards, textiles, and ceramics to print content on surfaces like paper, plastic, metal, glass, fabric, etc. The demand for printing machines is driven by the need for product labeling & branding, publication of books, newspapers & periodicals, and decoration of various surfaces. The advantages of printing machines include high production rates, versatility in printing various materials, consistent and repeatable results, and economic volumes for short & medium runs.

The Global printing machine market is estimated to be valued at US$ 47.6 billion in 2024 and is expected to exhibit a CAGR of 5.9% over the forecast period 2024 To 2031.

Key Takeaways

Key players operating in the printing machine market are Heidelberg Printing Machines AG, Koenig & Bauer AG, Bobst Group SA, KOMORI Corporation, and Rotatek S.A.

The packaging industry has been adopting flexible and digital printing to improve aesthetics and provide product information which is opening growth opportunities for printing machine manufacturers.

The Printing Machine Market Size is witnessing expansion in Asia Pacific and Middle East & Africa region due to growth of publishing, textile, and packaging industries in developing countries.

Market drivers

Rising demand from the packaging industry is a major factor contributing to the growth of the printing machine market. Growth in the e-commerce sector has increased the demand for customized and short run package printing which is driving the installation of digital & flexographic printing presses. The need for product identification and branding through labels and packaging is also positively impacting the market.

P

11:02 AM - Oct 09, 2024 (UTC)

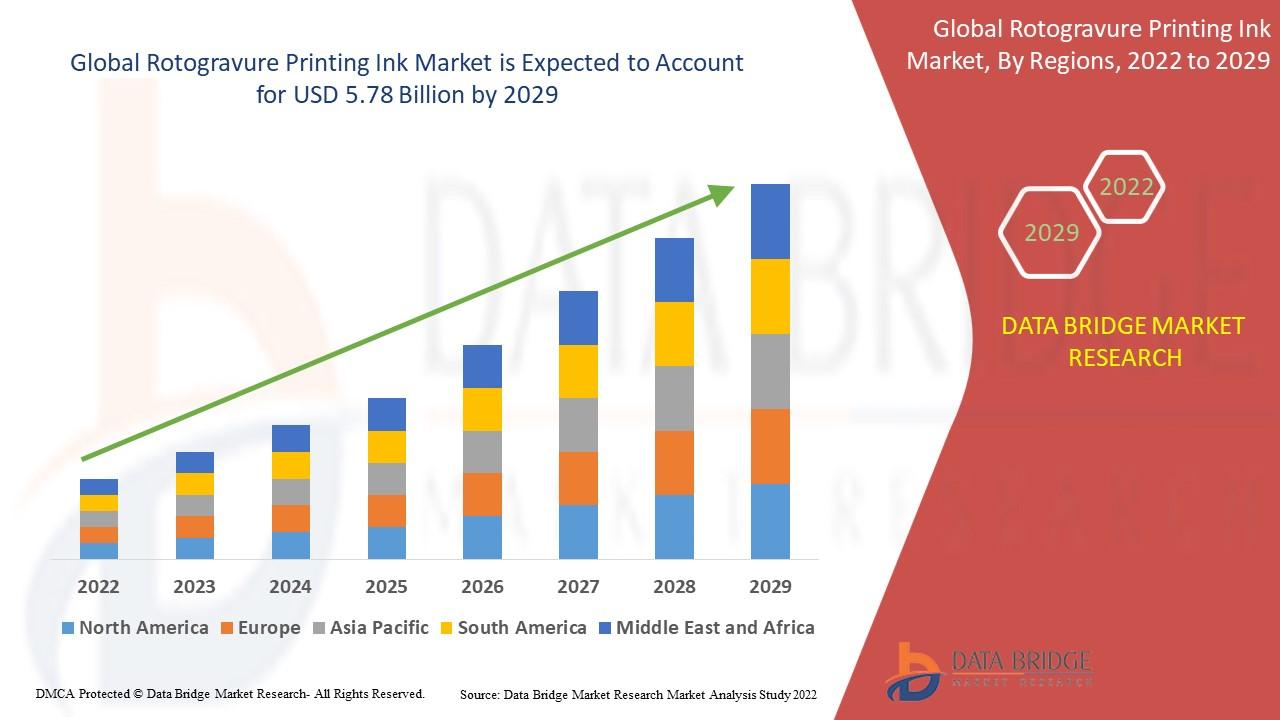

Global Rotogravure Printing Ink Market – Industry Trends and Forecast to 2029

09:24 AM - Jul 11, 2024 (UTC)

Gravure Printing Machine Market Outlook & Forecast to 2032 https://www.databridgemark...

07:17 AM - May 02, 2025 (UTC)

Ink Resins Market Size, Share, Growth Forecast 2023-2032

The Ink Resins Market Industry Report 2032 is an in depth study analyzing the current state of the Ink Resins Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on Ink Resins Market provides analysis of China market covering the industry trends, recent developments in the market and competitive landscape. Competitive analysis includes competitive information of leading players in China market, their company profiles, product portfolio, capacity, production, and company financials. In addition, report also provides upstream raw material analysis and downstream demand analysis along with the key development trends and sales channel analysis. Research study on Ink Resins Market also discusses the opportunity areas for investors.

Download Sample Report Copy From Here: https://www.acumenresearch...

The report provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Market Segmentation:

The worldwide market for ink resins is split based on type, printing process, printing ink, application, and geography.

Ink Resin Types

Acrylic

Polyamide

Polyurethane

Modified Rosin

Hydrocarbon Resin

Modified Cellulose

Ink Resins Printing Processes

Flexography

Lithography

Digital

Gravure

Others

Ink Resin Printing Inks

Water-based

UV-cured

Oil-based

Solvent-based

Ink Resin Applications

Printing and Publication

Flexible Packaging

Corrugated Cardboard & Cartons

Others

Table Of Contents: https://www.acumenresearch...

Market Players as below:

Some of the top ink resins companies offered in our report includes Harima Chemicals Group, Inc., BASF SE, Resinall Corp, Ingevity, OMNOVA Solutions Inc., Arakawa Chemical Industries Ltd., KRATON CORPORATION, Arkema, Evonik Industries AG, Gellner Industrial LLC, Shenghong Chemical, and Meilida Pigment Industry Co., Ltd.

Ask Query Here: Richardacumenresearchandconsulting.com or salesacumenresearchandconsulting.com

To Purchase this Premium Report@ https://www.acumenresearch...

The Ink Resins Market Industry Report 2032 is an in depth study analyzing the current state of the Ink Resins Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on Ink Resins Market provides analysis of China market covering the industry trends, recent developments in the market and competitive landscape. Competitive analysis includes competitive information of leading players in China market, their company profiles, product portfolio, capacity, production, and company financials. In addition, report also provides upstream raw material analysis and downstream demand analysis along with the key development trends and sales channel analysis. Research study on Ink Resins Market also discusses the opportunity areas for investors.

Download Sample Report Copy From Here: https://www.acumenresearch...

The report provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Market Segmentation:

The worldwide market for ink resins is split based on type, printing process, printing ink, application, and geography.

Ink Resin Types

Acrylic

Polyamide

Polyurethane

Modified Rosin

Hydrocarbon Resin

Modified Cellulose

Ink Resins Printing Processes

Flexography

Lithography

Digital

Gravure

Others

Ink Resin Printing Inks

Water-based

UV-cured

Oil-based

Solvent-based

Ink Resin Applications

Printing and Publication

Flexible Packaging

Corrugated Cardboard & Cartons

Others

Table Of Contents: https://www.acumenresearch...

Market Players as below:

Some of the top ink resins companies offered in our report includes Harima Chemicals Group, Inc., BASF SE, Resinall Corp, Ingevity, OMNOVA Solutions Inc., Arakawa Chemical Industries Ltd., KRATON CORPORATION, Arkema, Evonik Industries AG, Gellner Industrial LLC, Shenghong Chemical, and Meilida Pigment Industry Co., Ltd.

Ask Query Here: Richardacumenresearchandconsulting.com or salesacumenresearchandconsulting.com

To Purchase this Premium Report@ https://www.acumenresearch...

06:44 AM - May 03, 2024 (UTC)

Gravure Printing Inks Market Sales and Revenue Report 2023-2032

The Gravure Printing Inks Market Industry Report 2032 is an in depth study analyzing the current state of the Gravure Printing Inks Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on Gravure Printing Inks Market provides analysis of China market covering the industry trends, recent developments in the market and competitive landscape. Competitive analysis includes competitive information of leading players in China market, their company profiles, product portfolio, capacity, production, and company financials. In addition, report also provides upstream raw material analysis and downstream demand analysis along with the key development trends and sales channel analysis. Research study on Gravure Printing Inks Market also discusses the opportunity areas for investors.

Download Sample Report Copy From Here: https://www.acumenresearch...

The report provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Market Segmentation:

The worldwide market for gravure printing inks is split based on resin, technology, application, and geography.

Gravure Printing Ink Resins

Acrylic

Nitrocellulose

Polyamide

Polyurethane

Others (including Polyester, Maleic, Ketonic, and Polyvinyl)

Gravure Printing Ink Technologies

Solvent-based

Water-based

Others (including UV-curable)

Gravure Printing Ink Applications

Furniture

Packaging

Publication

Others (including Wrapping Paper, Wallpaper, Textile, and Label)

Table Of Contents: https://www.acumenresearch...

Market Players as below:

Some of the top gravure printing inks companies offered in our report includes Altana AG, Flint Group, SiegwerkDruckfarben AG & Co. KGaA, Huber Group, Royal Dutch Printing Ink Factories Van Son, Sakata INX Corporation, Sun Chemical Corporation, Toyo Ink Group, T&K TOKA Corporation, Wikoff Color Corporation, and Zeller+Gmelin GmbH & Co. KG.

Ask Query Here: Richardacumenresearchandconsulting.com or salesacumenresearchandconsulting.com

To Purchase this Premium Report@ https://www.acumenresearch...

The Gravure Printing Inks Market Industry Report 2032 is an in depth study analyzing the current state of the Gravure Printing Inks Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on Gravure Printing Inks Market provides analysis of China market covering the industry trends, recent developments in the market and competitive landscape. Competitive analysis includes competitive information of leading players in China market, their company profiles, product portfolio, capacity, production, and company financials. In addition, report also provides upstream raw material analysis and downstream demand analysis along with the key development trends and sales channel analysis. Research study on Gravure Printing Inks Market also discusses the opportunity areas for investors.

Download Sample Report Copy From Here: https://www.acumenresearch...

The report provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Market Segmentation:

The worldwide market for gravure printing inks is split based on resin, technology, application, and geography.

Gravure Printing Ink Resins

Acrylic

Nitrocellulose

Polyamide

Polyurethane

Others (including Polyester, Maleic, Ketonic, and Polyvinyl)

Gravure Printing Ink Technologies

Solvent-based

Water-based

Others (including UV-curable)

Gravure Printing Ink Applications

Furniture

Packaging

Publication

Others (including Wrapping Paper, Wallpaper, Textile, and Label)

Table Of Contents: https://www.acumenresearch...

Market Players as below:

Some of the top gravure printing inks companies offered in our report includes Altana AG, Flint Group, SiegwerkDruckfarben AG & Co. KGaA, Huber Group, Royal Dutch Printing Ink Factories Van Son, Sakata INX Corporation, Sun Chemical Corporation, Toyo Ink Group, T&K TOKA Corporation, Wikoff Color Corporation, and Zeller+Gmelin GmbH & Co. KG.

Ask Query Here: Richardacumenresearchandconsulting.com or salesacumenresearchandconsulting.com

To Purchase this Premium Report@ https://www.acumenresearch...

06:32 AM - May 03, 2024 (UTC)

Rotogravure Printing Ink Market Research Report 2025 | Size, Share, Trends, Growth and Forecast including Opportunities and Challenges

https://www.databridgemark...

https://www.databridgemark...

07:43 AM - May 08, 2025 (UTC)

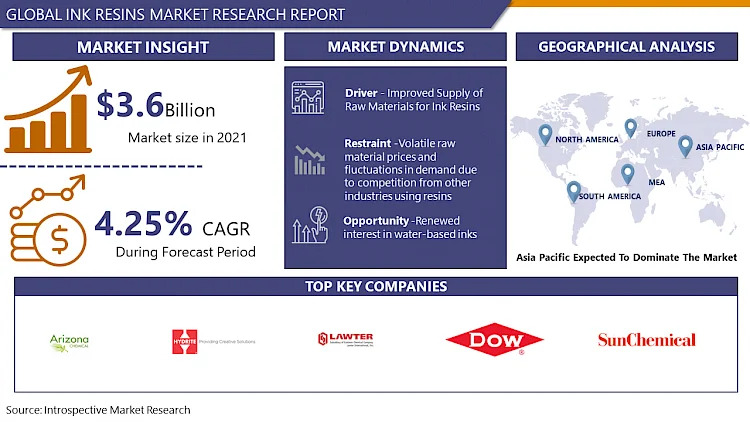

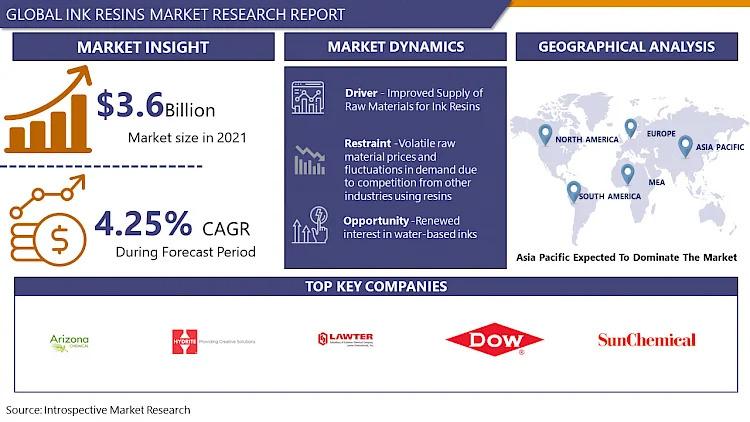

Ink Resins Market Size, Share, and Growth Trends for 2030

Global Ink Resins Market Size Was Valued at USD 3.6 Billion in 2022, and is Projected to Reach USD 5.02 Billion by 2030, Growing at a CAGR of 4.25% From 2023-2030.

The ink resins market refers to the sector dedicated to the production and distribution of resins specifically formulated for ink manufacturing. Ink resins play a pivotal role in the formulation of various types of inks, including flexographic, gravure, offset, and digital inks. These resins provide crucial properties such as adhesion, durability, gloss, and pigment dispersion, ensuring optimal print quality and performance. The market encompasses a wide range of resin types, including acrylic, polyamide, polyurethane, and rosin-based resins, tailored to meet the specific requirements of different ink formulations and printing processes. Factors driving the ink resins market growth include the expanding printing industry, technological advancements in resin formulation, growing demand for sustainable and eco-friendly ink solutions, and increasing investments in research and development to innovate new resin formulations.

Global Ink Resins Market Top Key Players:

Arizona Chemical (U.S.), Hydrite Chemical (U.S.), Lawter B.V. (U.S.), The Dow Chemical Company (U.S.), Sun Chemical(U.S.), Huntsman Corporation (U.S.), Emerald Performance Materials (U.S.), Celanese Corporation (U.S.), Wacker Chemie AG(Germany), BASF SE (Germany), Evonik Tego Chemie GmbH (Germany), Covestro AG (Germany),, Indulor (Germany), Lanxess (Germany), IGM Resins (Netherlands), DSM (Netherlands), Flint Group (Netherlands), Arakawa Chemical (Japan), Nippon Steel Chemical Co., Ltd. (Japan), DIC Corporation (Japan), Royal DSM N.V. (Netherlands), SK Chemicals Co., Ltd. (South Korea), LOTTE Chemical Corporation (South Korea), Jilin Chemical Industry Group Co., Ltd. (China), Sinopec Corporation (China),

Start Your Research with a Free Sample Report!

https://introspective

Global Ink Resins Market Size Was Valued at USD 3.6 Billion in 2022, and is Projected to Reach USD 5.02 Billion by 2030, Growing at a CAGR of 4.25% From 2023-2030.

The ink resins market refers to the sector dedicated to the production and distribution of resins specifically formulated for ink manufacturing. Ink resins play a pivotal role in the formulation of various types of inks, including flexographic, gravure, offset, and digital inks. These resins provide crucial properties such as adhesion, durability, gloss, and pigment dispersion, ensuring optimal print quality and performance. The market encompasses a wide range of resin types, including acrylic, polyamide, polyurethane, and rosin-based resins, tailored to meet the specific requirements of different ink formulations and printing processes. Factors driving the ink resins market growth include the expanding printing industry, technological advancements in resin formulation, growing demand for sustainable and eco-friendly ink solutions, and increasing investments in research and development to innovate new resin formulations.

Global Ink Resins Market Top Key Players:

Arizona Chemical (U.S.), Hydrite Chemical (U.S.), Lawter B.V. (U.S.), The Dow Chemical Company (U.S.), Sun Chemical(U.S.), Huntsman Corporation (U.S.), Emerald Performance Materials (U.S.), Celanese Corporation (U.S.), Wacker Chemie AG(Germany), BASF SE (Germany), Evonik Tego Chemie GmbH (Germany), Covestro AG (Germany),, Indulor (Germany), Lanxess (Germany), IGM Resins (Netherlands), DSM (Netherlands), Flint Group (Netherlands), Arakawa Chemical (Japan), Nippon Steel Chemical Co., Ltd. (Japan), DIC Corporation (Japan), Royal DSM N.V. (Netherlands), SK Chemicals Co., Ltd. (South Korea), LOTTE Chemical Corporation (South Korea), Jilin Chemical Industry Group Co., Ltd. (China), Sinopec Corporation (China),

Start Your Research with a Free Sample Report!

https://introspective

07:03 AM - Feb 19, 2024 (UTC)

Ink Resins Market Size, Share, and Growth Trends for 2030

Global Ink Resins Market Size Was Valued at USD 3.6 Billion in 2022, and is Projected to Reach USD 5.02 Billion by 2030, Growing at a CAGR of 4.25% From 2023-2030.

The manufacture, application, and distribution of resins designed especially for use in printing inks are all part of the ink resins market. These resins are essential to the production of flexographic, gravure, offset, and digital printing inks, among other kinds of ink. Essential characteristics of ink resins include adhesion, gloss, flexibility, durability, and resistance to chemicals for the printed surface. The rise of the packaging industry, rising demand for premium printing inks across a range of industries, including publishing, labels, textiles, and packaging, and developments in resin technology to satisfy changing consumer demands are the main factors propelling the market's expansion. Environmental rules that encourage the use of eco-friendly ink formulations, advancements in inkjet printing technology, and the trend toward digital printing solutions are some other factors that impact market dynamics.

Global Ink Resins Market Top Key Players:

Arizona Chemical (U.S.), Hydrite Chemical (U.S.), Lawter B.V. (U.S.), The Dow Chemical Company (U.S.), Sun Chemical(U.S.), Huntsman Corporation (U.S.), Emerald Performance Materials (U.S.), Celanese Corporation (U.S.), Wacker Chemie AG(Germany), BASF SE (Germany), Evonik Tego Chemie GmbH (Germany), Covestro AG (Germany),, Indulor (Germany), Lanxess (Germany), IGM Resins (Netherlands), DSM (Netherlands), Flint Group (Netherlands), Arakawa Chemical (Japan), Nippon Steel Chemical Co., Ltd. (Japan), DIC Corporation (Japan), Royal DSM N.V. (Netherlands), SK Chemicals Co., Ltd. (South Korea), LOTTE Chemical Corporation (South Korea), Jilin Chemical Industry Group Co., Ltd. (China), Sinopec Corporation (China),

Start Your Research with a Free Sample Report!

https://introspectivemarke...

Introspective Market Research is dedicated to delivering comprehensive market research studies that provide valuable insights and strategic guidance to businesses worldwide. Our reports are drafted with an utmost focus on reliability and accuracy.

Our market research study carefully examines the overall industry, covering all essential market fundamentals. Through an extensive range of primary and secondary sources, we establish a robust foundation for our finding

Global Ink Resins Market Size Was Valued at USD 3.6 Billion in 2022, and is Projected to Reach USD 5.02 Billion by 2030, Growing at a CAGR of 4.25% From 2023-2030.

The manufacture, application, and distribution of resins designed especially for use in printing inks are all part of the ink resins market. These resins are essential to the production of flexographic, gravure, offset, and digital printing inks, among other kinds of ink. Essential characteristics of ink resins include adhesion, gloss, flexibility, durability, and resistance to chemicals for the printed surface. The rise of the packaging industry, rising demand for premium printing inks across a range of industries, including publishing, labels, textiles, and packaging, and developments in resin technology to satisfy changing consumer demands are the main factors propelling the market's expansion. Environmental rules that encourage the use of eco-friendly ink formulations, advancements in inkjet printing technology, and the trend toward digital printing solutions are some other factors that impact market dynamics.

Global Ink Resins Market Top Key Players:

Arizona Chemical (U.S.), Hydrite Chemical (U.S.), Lawter B.V. (U.S.), The Dow Chemical Company (U.S.), Sun Chemical(U.S.), Huntsman Corporation (U.S.), Emerald Performance Materials (U.S.), Celanese Corporation (U.S.), Wacker Chemie AG(Germany), BASF SE (Germany), Evonik Tego Chemie GmbH (Germany), Covestro AG (Germany),, Indulor (Germany), Lanxess (Germany), IGM Resins (Netherlands), DSM (Netherlands), Flint Group (Netherlands), Arakawa Chemical (Japan), Nippon Steel Chemical Co., Ltd. (Japan), DIC Corporation (Japan), Royal DSM N.V. (Netherlands), SK Chemicals Co., Ltd. (South Korea), LOTTE Chemical Corporation (South Korea), Jilin Chemical Industry Group Co., Ltd. (China), Sinopec Corporation (China),

Start Your Research with a Free Sample Report!

https://introspectivemarke...

Introspective Market Research is dedicated to delivering comprehensive market research studies that provide valuable insights and strategic guidance to businesses worldwide. Our reports are drafted with an utmost focus on reliability and accuracy.

Our market research study carefully examines the overall industry, covering all essential market fundamentals. Through an extensive range of primary and secondary sources, we establish a robust foundation for our finding

07:41 AM - Apr 22, 2024 (UTC)

Zeen Enterprise: Leading Solvent-Based Inks Manufacturers in India

When it comes to printing on non-porous surfaces like plastic, foil, or metal, solvent-based inks are the ideal choice. These inks are known for their ability to adhere to challenging surfaces, making them perfect for industries like packaging, automotive, and advertising.

Zeen Enterprise is a top solvent-based inks manufacturer in India, providing high-performance inks that offer:

• Excellent Adhesion: Our solvent-based inks are formulated to bond seamlessly with a variety of substrates.

• Durability: These inks are resistant to water, UV light, and chemicals, ensuring that the print remains vibrant and intact over time.

• Versatility: Our solvent-based inks are suitable for multiple printing methods, including flexography, gravure, and screen printing.

As one of the leading solvent base inks manufacturers in India, we pride ourselves on producing inks that meet the highest industry standards for performance and safety.

https://www.z-inks.com/

When it comes to printing on non-porous surfaces like plastic, foil, or metal, solvent-based inks are the ideal choice. These inks are known for their ability to adhere to challenging surfaces, making them perfect for industries like packaging, automotive, and advertising.

Zeen Enterprise is a top solvent-based inks manufacturer in India, providing high-performance inks that offer:

• Excellent Adhesion: Our solvent-based inks are formulated to bond seamlessly with a variety of substrates.

• Durability: These inks are resistant to water, UV light, and chemicals, ensuring that the print remains vibrant and intact over time.

• Versatility: Our solvent-based inks are suitable for multiple printing methods, including flexography, gravure, and screen printing.

As one of the leading solvent base inks manufacturers in India, we pride ourselves on producing inks that meet the highest industry standards for performance and safety.

https://www.z-inks.com/

07:35 PM - Sep 29, 2024 (UTC)

Print Label Market Will Grow at Highest Pace Owing To Increased Demand for Packaged Food Items

The print label market involves various product labels that provide product information to consumers. Print labels can include barcode labels, product labels, nutrition facts labels, price labels, and other types of labels for food, beverage, pharmaceutical, chemical, and various consumer product packaging.

With the rising health-conscious consumer base, the Print Label Market Demand for nutrition info labels and organic product labels is growing significantly.

Get more insights: Print Label Market (https://articlescad.com/pr...

#CoherentMarketInsights #PrintLabelMarket #WetGlueLabels #PressureSensitiveLabels #LinerlessLabels #MultiPartTrackingLabels #Offset #Lithography #Gravure #Flexography

The print label market involves various product labels that provide product information to consumers. Print labels can include barcode labels, product labels, nutrition facts labels, price labels, and other types of labels for food, beverage, pharmaceutical, chemical, and various consumer product packaging.

With the rising health-conscious consumer base, the Print Label Market Demand for nutrition info labels and organic product labels is growing significantly.

Get more insights: Print Label Market (https://articlescad.com/pr...

#CoherentMarketInsights #PrintLabelMarket #WetGlueLabels #PressureSensitiveLabels #LinerlessLabels #MultiPartTrackingLabels #Offset #Lithography #Gravure #Flexography

12:45 PM - Nov 11, 2024 (UTC)

Understanding Plastic Printing Inks

Plastic printing inks are specifically developed to print on plastic substrates, such as polyethylene, polypropylene, and PVC. These inks need to be flexible, fast-drying, and provide a strong bond with the plastic surface.

Why Choose Plastic Printing Inks?

• Strong Adhesion: Bonds well with various types of plastic surfaces.

• Fast Drying: Reduces production time, making the process more efficient.

• High Opacity: Offers excellent coverage, even on dark or transparent materials.

Zeen Enterprise offers a comprehensive range of Plastic Printing Inks that cater to the specific needs of the plastic packaging industry, ensuring that your products are printed with precision and clarity.

https://www.z-inks.com/rot...

Plastic printing inks are specifically developed to print on plastic substrates, such as polyethylene, polypropylene, and PVC. These inks need to be flexible, fast-drying, and provide a strong bond with the plastic surface.

Why Choose Plastic Printing Inks?

• Strong Adhesion: Bonds well with various types of plastic surfaces.

• Fast Drying: Reduces production time, making the process more efficient.

• High Opacity: Offers excellent coverage, even on dark or transparent materials.

Zeen Enterprise offers a comprehensive range of Plastic Printing Inks that cater to the specific needs of the plastic packaging industry, ensuring that your products are printed with precision and clarity.

https://www.z-inks.com/rot...

12:34 PM - Aug 23, 2024 (UTC)

Global Rotogravure Printing Ink Market – Industry Trends and Forecast to 2029

11:30 AM - Oct 18, 2024 (UTC)

Printed Electronics Market Size, Share Analysis Report

"Printed Electronics Market research document assists business in every sphere of trade to take superior decisions, to tackle the toughest business questions and diminish the risk of failure. The market data provided in the report helps to discover diverse market opportunities present worldwide for Printed Electronics Market industry. A proficient team works meticulously with their potential capabilities to generate this finest market research report. By applying best-practice models and research methodologies, complete market analysis is performed in the winning Printed Electronics Marketing report to make sure that the report provides accurate market segmentation and insights for the success of client’s business.

Top players and brands are analysed with respect to their actions such as developments, product launches, acquisitions, mergers, joint ventures and competitive research in the market. General market conditions such as product price, profit, capacity, production, supply, demand, and market growth rate are also analysed in the wide ranging report which aids businesses decide several strategies. To produce this global market report, a team of multilingual researchers who are skilled at different languages come together with which they professionally execute market research globally. Printed Electronics Market is the promising and most suitable market report for the clients.

The printed electronics market is expected to witness market growth at a rate of 18.40% in the forecast period of 2021 to 2028.

Explore Further Details about This Research Printed Electronics Market Report https://www.databridgemark...

Printed Electronics Market Scope and Market Size

The printed electronics market is segmented on the basis of type and end users vertical. The growth among segments helps you analyse niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of printing technology, the printed electronics market has been segmented into Inkjet Printing, Screen Printing, Flexographic Printing, Gravure Printing, and Others.

On the basis of application, the printed electronics market has been segmented into displays, RFID tags, batteries, photovoltaics, sensors, lighting solutions or devices, and others.

On the basis of end-user, the prin

"Printed Electronics Market research document assists business in every sphere of trade to take superior decisions, to tackle the toughest business questions and diminish the risk of failure. The market data provided in the report helps to discover diverse market opportunities present worldwide for Printed Electronics Market industry. A proficient team works meticulously with their potential capabilities to generate this finest market research report. By applying best-practice models and research methodologies, complete market analysis is performed in the winning Printed Electronics Marketing report to make sure that the report provides accurate market segmentation and insights for the success of client’s business.

Top players and brands are analysed with respect to their actions such as developments, product launches, acquisitions, mergers, joint ventures and competitive research in the market. General market conditions such as product price, profit, capacity, production, supply, demand, and market growth rate are also analysed in the wide ranging report which aids businesses decide several strategies. To produce this global market report, a team of multilingual researchers who are skilled at different languages come together with which they professionally execute market research globally. Printed Electronics Market is the promising and most suitable market report for the clients.

The printed electronics market is expected to witness market growth at a rate of 18.40% in the forecast period of 2021 to 2028.

Explore Further Details about This Research Printed Electronics Market Report https://www.databridgemark...

Printed Electronics Market Scope and Market Size

The printed electronics market is segmented on the basis of type and end users vertical. The growth among segments helps you analyse niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of printing technology, the printed electronics market has been segmented into Inkjet Printing, Screen Printing, Flexographic Printing, Gravure Printing, and Others.

On the basis of application, the printed electronics market has been segmented into displays, RFID tags, batteries, photovoltaics, sensors, lighting solutions or devices, and others.

On the basis of end-user, the prin

11:48 AM - May 07, 2024 (UTC)

Understanding the Different Types of Print Labels

Label Design and Material Selection

The design and material used for a print label is determined by its intended purpose and environment. Factors like weather conditions, temperature variations, surfaces to adhere to, and shelf life all influence the optimal label material. For product labels that will experience harsh outdoor conditions, a weather resistant material like polyvinyl chloride (PVC) is commonly used. PVC labels can withstand heat, cold, moisture and abrasion. For indoor use where temperature and humidity are controlled, papers and films may suffice. Thermal transfer products are a cost-effective paper or film designed for direct thermal printing. If a permanent adhesive is needed, polypropylene or polyester materials are durable choices.

Printing Technologies for Labels

There are several different Print Labels methods suitable for producing labels at both small and large volumes. For short runs under 1000 labels, digital printing is a viable option. Technologies like inkjet and laser allow printing variable data in full color directly from a digital file. These provide a cost-effective solution for prototype, one-off or customized labels. For longer print runs, traditional printing methods become more economical. Flexography is commonly used for labels because of its ability to print on various substrates at high speeds. The image is etched onto a photopolymer plate and ink is transferred via raised surfaces on the plate. Flexo is ideal for printing on films, papers and plastic materials. Offset lithography provides superb print quality and can print multi-color process images. The image is first printed to a metal plate then transferred to rubber blanket cylinders before applying ink to the substrate. Offset is well-suited for photo-quality labels in runs above 5000 pieces. Rotogravure utilizes an engraved cylinder to apply ink in recessed cells. It is capable of long, unattended print runs into the millions of labels at very high speeds.

Design Considerations for Effective Labels

There are several design elements to consider when creating labels to maximize effectiveness and compliance. First is ensuring all required information is included as dictated by regulations. This may include ingredients, nutrition facts, manufacturing details, disposal instructions and more. Placement of text fields, barcodes and images should follow standard label layouts. Text size must be large enough to be readable, especially for small pa

Label Design and Material Selection

The design and material used for a print label is determined by its intended purpose and environment. Factors like weather conditions, temperature variations, surfaces to adhere to, and shelf life all influence the optimal label material. For product labels that will experience harsh outdoor conditions, a weather resistant material like polyvinyl chloride (PVC) is commonly used. PVC labels can withstand heat, cold, moisture and abrasion. For indoor use where temperature and humidity are controlled, papers and films may suffice. Thermal transfer products are a cost-effective paper or film designed for direct thermal printing. If a permanent adhesive is needed, polypropylene or polyester materials are durable choices.

Printing Technologies for Labels

There are several different Print Labels methods suitable for producing labels at both small and large volumes. For short runs under 1000 labels, digital printing is a viable option. Technologies like inkjet and laser allow printing variable data in full color directly from a digital file. These provide a cost-effective solution for prototype, one-off or customized labels. For longer print runs, traditional printing methods become more economical. Flexography is commonly used for labels because of its ability to print on various substrates at high speeds. The image is etched onto a photopolymer plate and ink is transferred via raised surfaces on the plate. Flexo is ideal for printing on films, papers and plastic materials. Offset lithography provides superb print quality and can print multi-color process images. The image is first printed to a metal plate then transferred to rubber blanket cylinders before applying ink to the substrate. Offset is well-suited for photo-quality labels in runs above 5000 pieces. Rotogravure utilizes an engraved cylinder to apply ink in recessed cells. It is capable of long, unattended print runs into the millions of labels at very high speeds.

Design Considerations for Effective Labels

There are several design elements to consider when creating labels to maximize effectiveness and compliance. First is ensuring all required information is included as dictated by regulations. This may include ingredients, nutrition facts, manufacturing details, disposal instructions and more. Placement of text fields, barcodes and images should follow standard label layouts. Text size must be large enough to be readable, especially for small pa

09:47 AM - Oct 15, 2024 (UTC)

Sponsored by

OWT

5 months ago