Exploring the Versatility and Applications of Phenolic Resins in Modern Industries

Phenolic resins are a class of synthetic polymers that are produced by the reaction of phenol or substituted phenol with formaldehyde. These resins are known for their excellent thermal stability, chemical resistance, and mechanical strength. The manufacturing process of phenolic resins involves the polycondensation of phenol and formaldehyde under controlled conditions, such as temperature, pressure, and catalyst type. The ratio of phenol to formaldehyde and the specific reaction conditions determine the final properties of the resin, such as its molecular weight, crosslink density, and functionality.

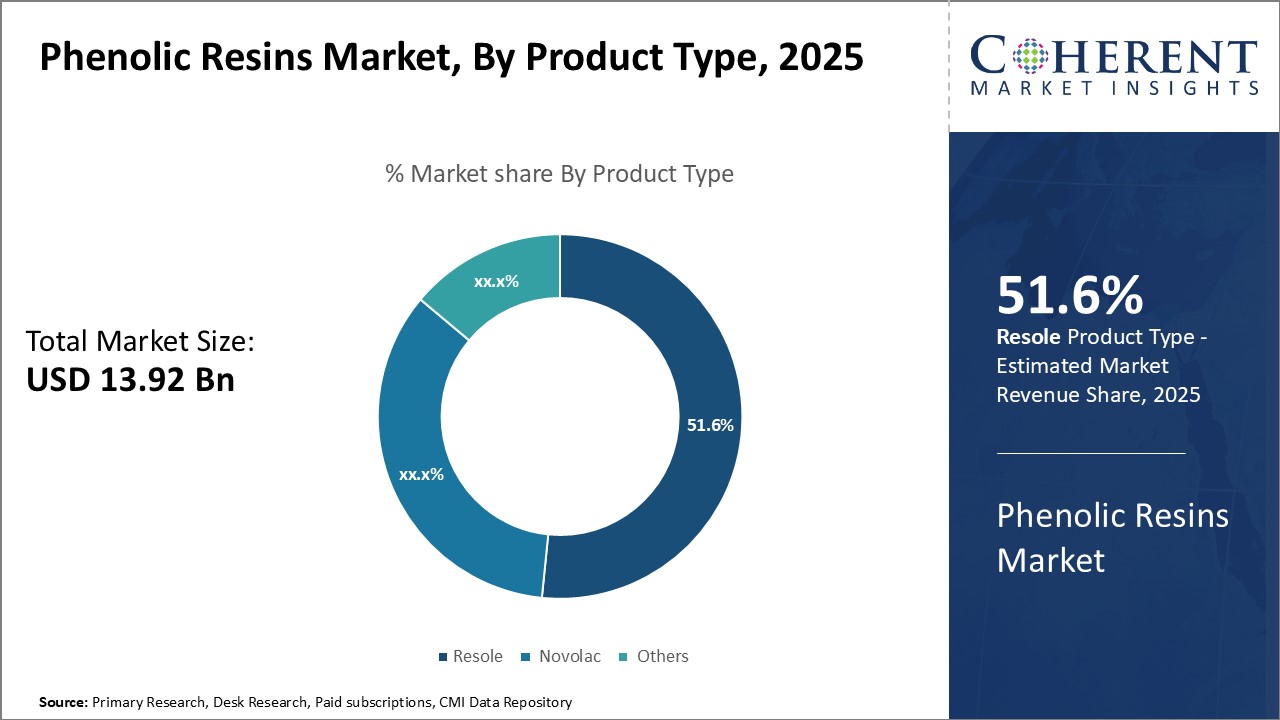

Phenolic Resins can be classified into two main categories: novolacs and resoles. Novolacs are produced with an excess of phenol and require an additional curing agent to achieve crosslinking, while resoles are synthesized with an excess of formaldehyde and can self-crosslink upon heating. The choice of resin type depends on the specific application and the desired properties of the final product.

Phenolic Resins-https://www.coherentmarket...

Phenolic resins are a class of synthetic polymers that are produced by the reaction of phenol or substituted phenol with formaldehyde. These resins are known for their excellent thermal stability, chemical resistance, and mechanical strength. The manufacturing process of phenolic resins involves the polycondensation of phenol and formaldehyde under controlled conditions, such as temperature, pressure, and catalyst type. The ratio of phenol to formaldehyde and the specific reaction conditions determine the final properties of the resin, such as its molecular weight, crosslink density, and functionality.

Phenolic Resins can be classified into two main categories: novolacs and resoles. Novolacs are produced with an excess of phenol and require an additional curing agent to achieve crosslinking, while resoles are synthesized with an excess of formaldehyde and can self-crosslink upon heating. The choice of resin type depends on the specific application and the desired properties of the final product.

Phenolic Resins-https://www.coherentmarket...

Phenolic Resins Market Size, Trends & Forecast, 2025-2032

Phenolic Resins Market size is estimated to be valued at USD 13.92 Bn in 2025 and is expected to expand at a CAGR of 4.6%, reaching USD 19.09 Bn by 2032.

https://www.coherentmarketinsights.com/market-insight/phenolic-resins-market-341

09:15 AM - Jun 20, 2025 (UTC)