Qishine Gasket Pipe Fitting Co., Ltd. relying on the abundant mineral resources and rich experience in the production of pipe fittings, specializing in the production of high-strength graphite composite gaskets and non-asbestos gaskets, PTFE gaskets, bolts, nuts, tees, elbows, bends, reducers, flanges, valves, steel pipes, etc. Qishine is dedicated to solving the problem occurring in various gas or fluid transportation of pumps, valves, and pipelines in power equipment, petrochemical, fine chemical, and power plants. Since entering the market, Qishine relies on strict quality management, never-ending technical innovation, and super high-cost performance. Our products have been exported to many countries and favored by customers.

12:57 AM - Mar 21, 2025 (UTC)

India is home to some of the leading manufacturers of silicone rubber gaskets, known for delivering high-quality, durable, and precision-engineered solutions for various industrial applications. These gaskets are widely used in automotive, pharmaceutical, food processing, electronics, and aerospace industries due to their excellent heat resistance, flexibility, and long service life.

Top Silicone rubber gasket manufacturer in India focus on using premium-grade raw materials and advanced manufacturing technologies to ensure superior performance and compliance with global standards. They offer customized solutions to meet specific client requirements, providing gaskets in various sizes, shapes, and hardness levels.

With a strong emphasis on quality control, timely delivery, and competitive pricing, Indian manufacturers are increasingly becoming preferred partners for domestic and international clients. If you're looking for reliable silicone rubber gasket suppliers, India offers a range of trusted options that combine innovation, technical expertise, and customer-centric service.

https://www.a1polymers.in/...

Top Silicone rubber gasket manufacturer in India focus on using premium-grade raw materials and advanced manufacturing technologies to ensure superior performance and compliance with global standards. They offer customized solutions to meet specific client requirements, providing gaskets in various sizes, shapes, and hardness levels.

With a strong emphasis on quality control, timely delivery, and competitive pricing, Indian manufacturers are increasingly becoming preferred partners for domestic and international clients. If you're looking for reliable silicone rubber gasket suppliers, India offers a range of trusted options that combine innovation, technical expertise, and customer-centric service.

https://www.a1polymers.in/...

09:28 AM - Jun 20, 2025 (UTC)

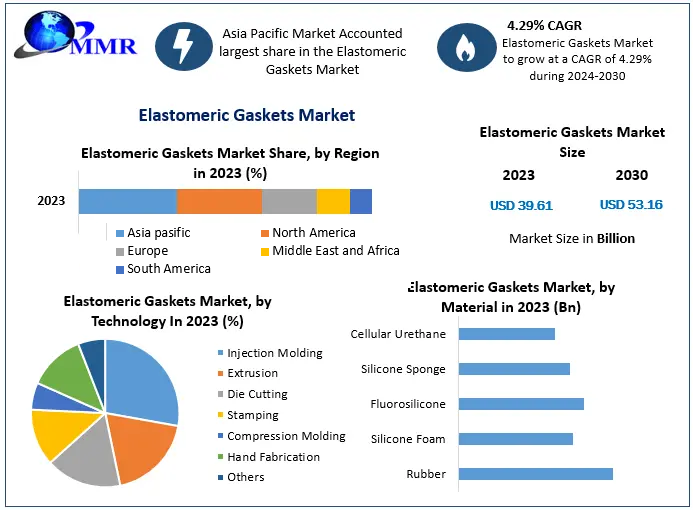

The Elastomeric gaskets are designed and developed for handling applications in a tough environment such as high-pressure and high-temperature liquids and gases.

https://www.maximizemarket...

https://www.maximizemarket...

Elastomeric Gaskets Market - Industry Analysis and Forecast 2030

Global Elastomeric Gaskets Market is expected to reach US$ 53.16 Bn at a CAGR of 4.29% during the forecast period 2030.

https://www.maximizemarketresearch.com/market-report/global-elastomeric-gaskets-market/92553/

07:27 AM - Jan 27, 2025 (UTC)

Why Gaskets and Springs Are Crucial for Equipment Longevity

As far as machines are concerned, gaskets are required for machinery that carry fluids-such as spray irrigation and hydraulic hose pipes to ensure that there is no leakage. They do this by forming a seal and making sure that water, oil, or any other liquid goes only from one place to another without getting wasted or contaminated.

Read More : https://circlekirrigation....

As far as machines are concerned, gaskets are required for machinery that carry fluids-such as spray irrigation and hydraulic hose pipes to ensure that there is no leakage. They do this by forming a seal and making sure that water, oil, or any other liquid goes only from one place to another without getting wasted or contaminated.

Read More : https://circlekirrigation....

10:12 AM - Jan 23, 2025 (UTC)

China Flange Gasket Bolt Nut Kits Manufacturer Co., Ltd. (https://www.flangegasketbo... is a professional pipeline products supplier in China, who mainly provides flanges, gaskets, bolt & nut kits and other pipe & fitting products. We have rich experience in projects and professional service, and can provide pipe & fittings with very good quality for global customers.

We are committed to becoming a highly efficient one-stop service supplier for pipe & fitting product procurement, saving time and costs for customers. We are an ideal partner for EPC companies and pipeline construction projects.

Professional service, competitive price, and excellent quality mean long-term win-win cooperation. Please give us a chance to work together. It would be a great start of pleasure cooperation. If you have any questions, do not hesitate to contact us. We Are reliable Chinese Manufacturer of pipe & fitting products which is worthy of your trust.

We are committed to becoming a highly efficient one-stop service supplier for pipe & fitting product procurement, saving time and costs for customers. We are an ideal partner for EPC companies and pipeline construction projects.

Professional service, competitive price, and excellent quality mean long-term win-win cooperation. Please give us a chance to work together. It would be a great start of pleasure cooperation. If you have any questions, do not hesitate to contact us. We Are reliable Chinese Manufacturer of pipe & fitting products which is worthy of your trust.

02:31 AM - Mar 20, 2025 (UTC)

Avoid Downtime: Use Custom Seals for Pumps and Valves Designed to Last

Avoid costly breakdowns and production delays with Custom Seals for Pump and Valve systems from Airex Rubber. We specialize in designing and manufacturing precision-engineered rubber molded parts, custom gaskets, and seals tailored to the exact needs of the pump and valve industry. Our custom seals are built to withstand high pressure, extreme temperatures, and aggressive media, ensuring long-lasting performance and minimal maintenance. Whether you're upgrading existing systems or building new equipment, trust Airex Rubber to deliver reliable, durable, and perfectly fitting solutions that help you run operations smoothly and efficiently. Optimize your system’s sealing performance—choose custom, choose quality.

Know More: https://www.airexrubber.co...

#CustomSealsForPumpandvalve

#CustommoldedPartsforpumpandvalveindustries

#custommoldedpartsforpumpandvalveindustriesprice

Avoid costly breakdowns and production delays with Custom Seals for Pump and Valve systems from Airex Rubber. We specialize in designing and manufacturing precision-engineered rubber molded parts, custom gaskets, and seals tailored to the exact needs of the pump and valve industry. Our custom seals are built to withstand high pressure, extreme temperatures, and aggressive media, ensuring long-lasting performance and minimal maintenance. Whether you're upgrading existing systems or building new equipment, trust Airex Rubber to deliver reliable, durable, and perfectly fitting solutions that help you run operations smoothly and efficiently. Optimize your system’s sealing performance—choose custom, choose quality.

Know More: https://www.airexrubber.co...

#CustomSealsForPumpandvalve

#CustommoldedPartsforpumpandvalveindustries

#custommoldedpartsforpumpandvalveindustriesprice

05:22 AM - Jun 26, 2025 (UTC)

Explore premium Sanitary Clamp Fittings at SteelTube.co.in, designed for hygienic and high-purity applications. Our stainless steel clamp fittings ensure leak-proof connections, easy installation, and durability for food, beverage, dairy, and pharmaceutical industries. Available in various sizes and configurations, our fittings meet international standards for safety and hygiene. Whether you need tri-clamp fittings, ferrules, or gaskets, we provide the best solutions for your sanitary piping systems. Shop now for reliable and corrosion-resistant sanitary fittings.

06:35 AM - Mar 15, 2025 (UTC)

The global rubber market is set to experience steady growth due to its extensive applications in automotive, aerospace, medical, defense, agriculture, and industrial manufacturing. Rubber, both natural and synthetic, is essential for producing tires, seals, hoses, gaskets, footwear, and industrial components. Read More: https://bityl.co/S6KA

Between 2025 and 2034, the global rubber market is projected to grow at a CAGR of 5.0%, driven by increasing demand from North America, Europe, and Asia. The growth is supported by technological advancements, rising industrialization, and the expansion of eco-friendly rubber alternatives.

Between 2025 and 2034, the global rubber market is projected to grow at a CAGR of 5.0%, driven by increasing demand from North America, Europe, and Asia. The growth is supported by technological advancements, rising industrialization, and the expansion of eco-friendly rubber alternatives.

06:15 AM - Feb 17, 2025 (UTC)

Silicone Foam

Silicone foam is a general-purpose material characterized by its lightweight, flexible, and tough nature. It has high thermal and acoustic insulation, shock absorption, and withstands harsh temperatures. Silcone foam finds application in a wide range of industries such as automobiles, electronics, and building. Silicone foam is perfectly suited for sealing, gaskets, and padding. For more details visit : https://senmatape.com/pro_...

Silicone foam is a general-purpose material characterized by its lightweight, flexible, and tough nature. It has high thermal and acoustic insulation, shock absorption, and withstands harsh temperatures. Silcone foam finds application in a wide range of industries such as automobiles, electronics, and building. Silicone foam is perfectly suited for sealing, gaskets, and padding. For more details visit : https://senmatape.com/pro_...

06:56 AM - Mar 08, 2025 (UTC)

High Temperature Gasket Materials Market to Surge Owing to Aftermarket Service Growth

High Temperature Gasket Materials Market encompasses sealing products engineered to withstand extreme heat and chemical exposure in industries such as automotive, power generation, petrochemicals, and aerospace. These gaskets are fabricated from advanced materials—graphite, ceramic fiber, composite elastomers—offering superior thermal stability, chemical resistance, and mechanical robustness.

By minimizing leakage and extending equipment life, they address stringent safety standards and operational efficiency requirements, reducing downtime and maintenance costs. The need for reliable sealing solutions grows alongside industrial expansion, stringent emission norms, and the rising High Temperature Gasket Materials Market Demand for energy-efficient systems. Ongoing investments in research and development drive innovation in product formulations and quality assurance.

High Temperature Gasket Materials Market-https://www.coherentmarket...

High Temperature Gasket Materials Market encompasses sealing products engineered to withstand extreme heat and chemical exposure in industries such as automotive, power generation, petrochemicals, and aerospace. These gaskets are fabricated from advanced materials—graphite, ceramic fiber, composite elastomers—offering superior thermal stability, chemical resistance, and mechanical robustness.

By minimizing leakage and extending equipment life, they address stringent safety standards and operational efficiency requirements, reducing downtime and maintenance costs. The need for reliable sealing solutions grows alongside industrial expansion, stringent emission norms, and the rising High Temperature Gasket Materials Market Demand for energy-efficient systems. Ongoing investments in research and development drive innovation in product formulations and quality assurance.

High Temperature Gasket Materials Market-https://www.coherentmarket...

09:49 AM - Jun 17, 2025 (UTC)

Excel Rubber Industries Inc. is a leading provider of high-quality rubber products, specializing in custom-molded and extruded solutions for diverse industries. Our product range includes EPDM sponge cords, silicone rubber cords, rubber seals, gaskets, and more, designed to deliver superior durability and performance.

With decades of experience and state-of-the-art manufacturing capabilities, we cater to industries like automotive, aerospace, construction, and healthcare. At Excel Rubber Industries Inc., we are committed to innovation, precision, and customer satisfaction, making us a trusted name in the rubber manufacturing sector.

Connect with us on ChatterChat to explore our product range, stay updated on our latest innovations, and discover how we can meet your rubber product needs!

https://chatterchat.com/ex...

With decades of experience and state-of-the-art manufacturing capabilities, we cater to industries like automotive, aerospace, construction, and healthcare. At Excel Rubber Industries Inc., we are committed to innovation, precision, and customer satisfaction, making us a trusted name in the rubber manufacturing sector.

Connect with us on ChatterChat to explore our product range, stay updated on our latest innovations, and discover how we can meet your rubber product needs!

https://chatterchat.com/ex...

Let's Chat

ChatterChat is a Social Networking Platform. With our new feature, user can wonder posts, photos,

https://chatterchat.com/excelrubberindustries

01:45 PM - Jan 07, 2025 (UTC)

We can say exactly, that technical plates can be used for the production of sealing gaskets in fixed joints https://vechorka.com.ua/bu... and as flooring, which ensures reliability and durability in operation. These materials have increased flexibility and wear resistance, which makes them indispensable for use in construction and industry. Technical rubber plates are available in different thicknesses, starting from 1 mm to 50 mm, which allows you to choose the optimal option for specific tasks.

08:59 AM - Feb 27, 2025 (UTC)

Alfa Laval Jwsp 26 C 100 Spares

https://amafmarine.com/pro...

The Alfa Laval JWSP 26 C 100 is a high-performance freshwater generator designed for marine use. Genuine spare parts are required to keep it operating at peak efficiency. AMAF Marine offers a wide choice of high-quality Alfa Laval JWSP 26 C 100 spare parts, such as heat exchanger components, ejector pumps, and gaskets. Our spare parts are reliable, durable, and compatible with your equipment, reducing downtime and increasing efficiency.

https://amafmarine.com/pro...

The Alfa Laval JWSP 26 C 100 is a high-performance freshwater generator designed for marine use. Genuine spare parts are required to keep it operating at peak efficiency. AMAF Marine offers a wide choice of high-quality Alfa Laval JWSP 26 C 100 spare parts, such as heat exchanger components, ejector pumps, and gaskets. Our spare parts are reliable, durable, and compatible with your equipment, reducing downtime and increasing efficiency.

07:35 AM - Feb 03, 2025 (UTC)

Sponsored by

OWT

5 months ago

Dwngo social network website

Dwngo – The Social Media Platform! * Share your thoughts & ideas * Publish blogs & trending stories * Connect, engage & grow your networkJoin now & be part of the future of social networking! #SocialMedia #Blogging #Dwngo --https://dwngo.com/

Excel Rubber Industries Inc. is a renowned manufacturer and supplier of premium rubber products, offering innovative and durable solutions for various industries. Our expertise lies in creating custom-molded and extruded products, including EPDM sponge cords, silicone rubber cords, rubber seals, gaskets, and more, tailored to meet precise industry needs.

With cutting-edge manufacturing technology and a commitment to quality, we serve sectors like automotive, aerospace, construction, and healthcare. At Excel Rubber Industries Inc., we prioritize customer satisfaction by delivering reliable and high-performing rubber components that exceed expectations.

Join us on ConfEngine to learn more about our offerings, stay updated with our latest advancements, and explore how our products can enhance your industrial applications!

https://confengine.com/use...

With cutting-edge manufacturing technology and a commitment to quality, we serve sectors like automotive, aerospace, construction, and healthcare. At Excel Rubber Industries Inc., we prioritize customer satisfaction by delivering reliable and high-performing rubber components that exceed expectations.

Join us on ConfEngine to learn more about our offerings, stay updated with our latest advancements, and explore how our products can enhance your industrial applications!

https://confengine.com/use...

01:48 PM - Jan 07, 2025 (UTC)

High-Quality Aerospace Rubber Extrusions for Aircraft Sealing & Insulation

Looking for durable and precision-engineered aerospace rubber extrusions? Airex Rubber specializes in high-performance rubber solutions designed for aircraft sealing, insulation, and vibration control. Our customized rubber extrusions meet the strictest industry standards, ensuring superior resistance to extreme temperatures, pressure variations, and harsh environmental conditions. Whether you need seals, gaskets, or insulation components, we deliver reliable, aerospace-grade solutions tailored to your needs.

🔹 Trusted quality & precision

🔹 Lightweight, durable & high-performance materials

🔹 Custom & standard aerospace rubber extrusions

Read More: https://www.airexrubber.co...

#AerospaceRubberExtrusions

Looking for durable and precision-engineered aerospace rubber extrusions? Airex Rubber specializes in high-performance rubber solutions designed for aircraft sealing, insulation, and vibration control. Our customized rubber extrusions meet the strictest industry standards, ensuring superior resistance to extreme temperatures, pressure variations, and harsh environmental conditions. Whether you need seals, gaskets, or insulation components, we deliver reliable, aerospace-grade solutions tailored to your needs.

🔹 Trusted quality & precision

🔹 Lightweight, durable & high-performance materials

🔹 Custom & standard aerospace rubber extrusions

Read More: https://www.airexrubber.co...

#AerospaceRubberExtrusions

06:12 AM - Mar 18, 2025 (UTC)