Cartridge Filter | Pearl Water Technologies

A Cartridge Filter is a cylindrical filtration component used in water purifiers to trap and remove physical impurities like dust, sand, rust, and suspended particles. It is typically made from materials like spun polypropylene or activated carbon and comes in various micron ratings depending on the filtration need. Cartridge filters are easy to install, cost-effective, and essential for maintaining clean and safe water. They are commonly used as sediment or carbon filters in multi-stage water purification systems.

Visit Us for More Info 👉 https://pearlwater.in/cart...

A Cartridge Filter is a cylindrical filtration component used in water purifiers to trap and remove physical impurities like dust, sand, rust, and suspended particles. It is typically made from materials like spun polypropylene or activated carbon and comes in various micron ratings depending on the filtration need. Cartridge filters are easy to install, cost-effective, and essential for maintaining clean and safe water. They are commonly used as sediment or carbon filters in multi-stage water purification systems.

Visit Us for More Info 👉 https://pearlwater.in/cart...

09:02 AM - Jun 03, 2025 (UTC)

"Hernia Repair Mesh Market" 2025 Research Report provides comprehensive insights into historical and current market trends, evaluating key aspects such as production costs, market size, share, and growth. A notable trend in the global Hernia Repair Mesh industry is the diversification of product offerings, including types such as [Polypropylene Hernia Mesh, Polyester Hernia Mesh, Biologic Hernia Mesh] and applications like [MAPPS1], fueling rapid expansion. Furthermore, the report explores successful marketing strategies, contributions from major industry players, recent innovations, and various analytical approaches.

Browse Detailed TOC of Hernia Repair Mesh Market report which is spread across 106+ Pages, Tables and Figures with Charts that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

https://www.globalmarketst...

Browse Detailed TOC of Hernia Repair Mesh Market report which is spread across 106+ Pages, Tables and Figures with Charts that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

https://www.globalmarketst...

03:29 AM - Apr 07, 2025 (UTC)

Synthetic Ropes Market to Soar Owing to Marine Demand

The Global Synthetic Ropes Market is estimated to be valued at US$ 2.12 Bn in 2025 and is expected to exhibit a CAGR of 6.0% over the forecast period 2025 to 2032.

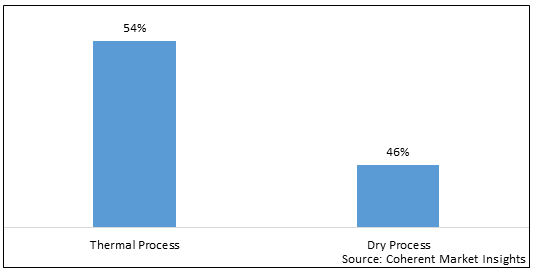

Synthetic ropes are engineered from high–strength polymers such as nylon, polyester, and polypropylene, offering superior tensile strength, reduced weight, and excellent resistance to abrasion and chemicals compared with traditional natural fibers. These ropes find widespread applications across marine mooring, offshore drilling, construction lifting, mining haulage, and adventure sports, where safety, durability, and ease of handling drive business growth. The evolving market dynamics reflect increasing emphasis on lightweight solutions in the shipping industry and renewable-energy projects, fueling market growth and shaping industry trends.

Get more insights on, Synthetic Ropes Market- https://www.patreon.com/po...

#CoherentMarketInsights #SyntheticRopes #SyntheticRopesMarket #SyntheticRopesMarketInsights #Polyethylene #Polypropylene

The Global Synthetic Ropes Market is estimated to be valued at US$ 2.12 Bn in 2025 and is expected to exhibit a CAGR of 6.0% over the forecast period 2025 to 2032.

Synthetic ropes are engineered from high–strength polymers such as nylon, polyester, and polypropylene, offering superior tensile strength, reduced weight, and excellent resistance to abrasion and chemicals compared with traditional natural fibers. These ropes find widespread applications across marine mooring, offshore drilling, construction lifting, mining haulage, and adventure sports, where safety, durability, and ease of handling drive business growth. The evolving market dynamics reflect increasing emphasis on lightweight solutions in the shipping industry and renewable-energy projects, fueling market growth and shaping industry trends.

Get more insights on, Synthetic Ropes Market- https://www.patreon.com/po...

#CoherentMarketInsights #SyntheticRopes #SyntheticRopesMarket #SyntheticRopesMarketInsights #Polyethylene #Polypropylene

11:54 AM - Jun 04, 2025 (UTC)

Aluminum Laminated Film Market is Estimated to Witness High Growth Owing to Rising Demand for Flexible Electronics Packaging.

Aluminum laminated film, also known as aluminum foil composite film, is a multi-layered film consisting of an aluminum foil between two substrate layers. The substrate layers are usually thermoplastic polymers like polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) etc. Aluminum laminated films are widely used in flexible packaging applications due to their desirable moisture and oxygen barrier properties, oil resistance and flame resistance.

Aluminum Laminated Film Market is estimated to be valued at USD 69.9 Mn in 2025 and is expected to reach USD 206.1 Mn in 2032, exhibiting a compound annual growth rate (CAGR) of 16.7% from 2025 to 2032.

Aluminum Laminated Film Market

https://www.coherentmarket...

Get More Insights On Aluminum Laminated Film Market

https://www.zupyak.com/p/4...

#AluminumLaminatedFilmMarket , #AluminumLaminatedFilmMarketsize , #AluminumLaminatedFilmMarketshare , #AluminumLaminatedFilmMarketApplication , #AluminumLaminatedFilmM

Aluminum laminated film, also known as aluminum foil composite film, is a multi-layered film consisting of an aluminum foil between two substrate layers. The substrate layers are usually thermoplastic polymers like polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) etc. Aluminum laminated films are widely used in flexible packaging applications due to their desirable moisture and oxygen barrier properties, oil resistance and flame resistance.

Aluminum Laminated Film Market is estimated to be valued at USD 69.9 Mn in 2025 and is expected to reach USD 206.1 Mn in 2032, exhibiting a compound annual growth rate (CAGR) of 16.7% from 2025 to 2032.

Aluminum Laminated Film Market

https://www.coherentmarket...

Get More Insights On Aluminum Laminated Film Market

https://www.zupyak.com/p/4...

#AluminumLaminatedFilmMarket , #AluminumLaminatedFilmMarketsize , #AluminumLaminatedFilmMarketshare , #AluminumLaminatedFilmMarketApplication , #AluminumLaminatedFilmM

Aluminum Laminated Film Market Share & YoY Growth Rate, 2032

Aluminum Laminated Film Market size is growing with a CAGR of 16.7% in the prediction period and it crosses USD 206.1 Mn in 2032 from USD 69.9 Mn in 2025.

https://www.coherentmarketinsights.com/market-insight/aluminum-laminated-film-market-3830

06:59 AM - May 21, 2025 (UTC)

A Pre Filter Cartridge | Pearl Water Technologies

A Pre-Filter Cartridge is the first stage of filtration in a water purifier, especially in reverse osmosis (RO) systems. It is designed to remove large particles like dust, sand, rust, and other visible impurities from the incoming water before it reaches the main RO membrane. By doing so, it protects the RO membrane and other internal filters from clogging and damage, thereby extending their lifespan and improving overall purification performance. Pre-filter cartridges are typically made of polypropylene or spun fiber material and are easy to replace. Regular maintenance ensures consistent water flow and effective filtration.

Visit Us 👉 https://pearlwater.in/ro-f...

A Pre-Filter Cartridge is the first stage of filtration in a water purifier, especially in reverse osmosis (RO) systems. It is designed to remove large particles like dust, sand, rust, and other visible impurities from the incoming water before it reaches the main RO membrane. By doing so, it protects the RO membrane and other internal filters from clogging and damage, thereby extending their lifespan and improving overall purification performance. Pre-filter cartridges are typically made of polypropylene or spun fiber material and are easy to replace. Regular maintenance ensures consistent water flow and effective filtration.

Visit Us 👉 https://pearlwater.in/ro-f...

10:22 AM - May 23, 2025 (UTC)

Hernia Repair Devices Market driven by Increasing Hernia Surgeries

The Global Hernia Repair Devices Market is estimated to be valued at USD 6.48 Bn in 2025 and is expected to exhibit a CAGR of 4.3% over the forecast period 2025 to 2032.

The hernia repair devices market comprises various products used in surgical repair of hernias, including Hernia meshes, tissue fixation devices, and other devices. Hernia meshes are the most commonly used implants for hernia repair and come in a variety of shapes and materials like polypropylene mesh and PTFE mesh. Advances in mesh designs and fixation methods have enabled better hernia repair outcomes with lower rates of complications and recurrence.

Get more insights on, Hernia Repair Devices Market- https://timessquarereporte...

#CoherentMarketInsights #HerniaRepairDevicesMarket #HerniaRepairDevices #HerniaRepairDevicesMarketInsights

The Global Hernia Repair Devices Market is estimated to be valued at USD 6.48 Bn in 2025 and is expected to exhibit a CAGR of 4.3% over the forecast period 2025 to 2032.

The hernia repair devices market comprises various products used in surgical repair of hernias, including Hernia meshes, tissue fixation devices, and other devices. Hernia meshes are the most commonly used implants for hernia repair and come in a variety of shapes and materials like polypropylene mesh and PTFE mesh. Advances in mesh designs and fixation methods have enabled better hernia repair outcomes with lower rates of complications and recurrence.

Get more insights on, Hernia Repair Devices Market- https://timessquarereporte...

#CoherentMarketInsights #HerniaRepairDevicesMarket #HerniaRepairDevices #HerniaRepairDevicesMarketInsights

Hernia Repair Devices Market Witnessing High Growth Owing to Technological Advancements in Hernia Repair Mesh and Stapling Equipment | Times Square Reporter

The Global Hernia Repair Devices Market is estimated to be valued at USD 6.48 Bn in 2025 and is expected to exhibit a CAGR of 4.3% over the forecast p...

https://timessquarereporter.com/business/hernia-repair-devices-market-witnessing-high-growth-owing-to-technological-advancements-in-hernia-repair-mesh-and-stapling-equipment

03:57 PM - Apr 14, 2025 (UTC)

Sackora supplies high-quality woven polypropylene bags across Canada. From custom sacks to bulk poly bags, we serve agriculture, industrial, and commercial sectors. As a trusted polypropylene packaging supplier, we deliver durable, affordable solutions tailored to your business. Visit Sackora.com to explore our full range and request a quote. For more visit https://sackora.com

03:35 PM - May 22, 2025 (UTC)

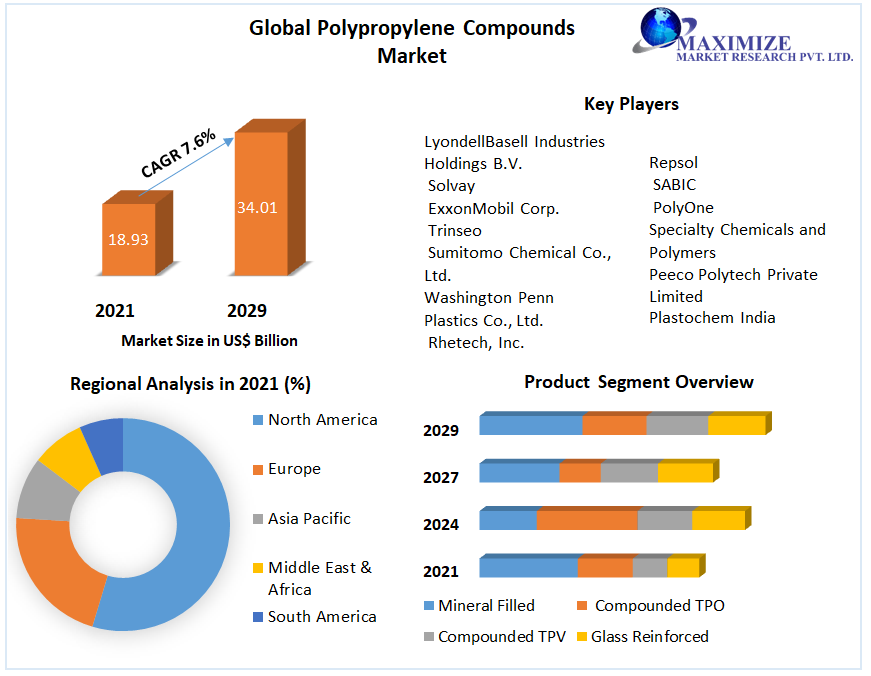

Polypropylene Compounds Market size was valued at US$ 18.93 Bn. in 2021 and the total revenue is expected to grow at a CAGR of 7.6% from 2022 to 2029, reaching nearly US$ 34.01 Bn.

https://www.maximizemarket...

https://www.maximizemarket...

Polypropylene Compounds Market: Global Industry Analysis and Forecast

Polypropylene Compounds Market size was valued at US$ 18.93 Bn. in 2021 and the total revenue is expected to grow at a CAGR of 7.6%.

https://www.maximizemarketresearch.com/market-report/global-polypropylene-compounds-market/100599/

05:52 AM - Apr 11, 2025 (UTC)

IGBT Snubber Capacitors

Deki Electronics offers high-performance IGBT Snubber Capacitors designed to protect power semiconductor devices from voltage spikes. These capacitors ensure efficient energy absorption, improved reliability, and enhanced performance in industrial and power electronic applications.

Visit; https://www.dekielectronic...

Deki Electronics offers high-performance IGBT Snubber Capacitors designed to protect power semiconductor devices from voltage spikes. These capacitors ensure efficient energy absorption, improved reliability, and enhanced performance in industrial and power electronic applications.

Visit; https://www.dekielectronic...

08:01 AM - Apr 08, 2025 (UTC)

Sponsored by

OWT

5 months ago

Sackora is a Canadian supplier of premium woven polypropylene bags. We provide bulk poly bags and custom sacks to the commercial, industrial, and agricultural sectors. As a reputable provider of polypropylene packaging, we offer long-lasting, reasonably priced solutions customized for your company. See our entire selection and get a quote at Sackora.com. For more visit https://sackora.com

09:54 PM - May 22, 2025 (UTC)

Polypropylene Film Capacitors

Deki Electronics’ Polypropylene Film Capacitors deliver high performance in high-frequency and voltage applications, offering durability, low loss, and stability—perfect for lighting, automotive, and industrial use with long operational life and reliable efficiency.

Visit: https://www.dekielectronic...

Deki Electronics’ Polypropylene Film Capacitors deliver high performance in high-frequency and voltage applications, offering durability, low loss, and stability—perfect for lighting, automotive, and industrial use with long operational life and reliable efficiency.

Visit: https://www.dekielectronic...

05:37 AM - Apr 22, 2025 (UTC)

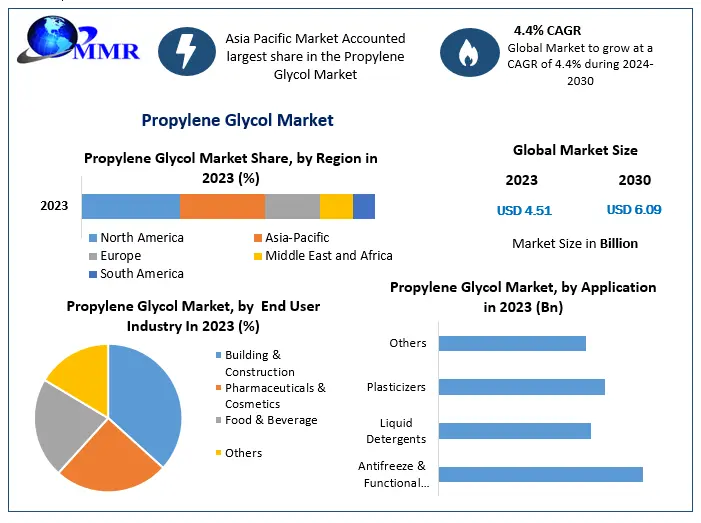

Propylene Glycol Market size was valued at US$ 4.51 Bn. in 2023 and transportation is one of the dominating segments reviewed in our report and dominating the Global Polypropylene Market.

https://www.maximizemarket...

https://www.maximizemarket...

Propylene Glycol Market- Global Analysis and Forecast 2030

Propylene Glycol Market size was valued at US$ 4.51 Bn. in 2023 and transportation is one of the dominating segments reviewed in our report

https://www.maximizemarketresearch.com/market-report/global-propylene-glycol-market/33146/

10:33 AM - Apr 21, 2025 (UTC)

Sackora provides premium woven polypropylene bags all around Canada. We serve agricultural, industrial, and commercial industries from bespoke sacks to bulk poly bags. Being a reliable polypropylene packaging provider, we provide economical, long-lasting solutions fit for your company. Visit Sackora.com to see our whole selection and ask for a price. For more visit https://sackora.com

05:39 PM - May 22, 2025 (UTC)

Plastic Packaging Market to Grow Rapidly on E-commerce Packaging Demand

Growing Plastic Packaging Market Demand for sustainable, lightweight and tamper-evident packaging is fueling market expansion. The rise of e-commerce has heightened need for robust protective packaging to prevent damage during transit. In food and beverage, flexible pouches and resealable containers are favored for convenience and portion control. Healthcare applications demand vial caps, blister packs and sachets with precise dosing and sterility.

Plastic packaging encompasses a wide range of products including films, containers, bottles, closures and pouches made from materials such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), polypropylene (PP) and polystyrene (PS). These solutions offer light weight, exceptional barrier properties against moisture and oxygen, high durability, chemical resistance and ease of molding into complex shapes.

Plastic Packaging Market

https://www.coherentmarket...

#PlasticPackaging ,#SustainablePackaging,#EcoFriendlyPlastics,#BioBasedPolymers,

#PackagingInnovation ,#Coherentmarketinsights.

Growing Plastic Packaging Market Demand for sustainable, lightweight and tamper-evident packaging is fueling market expansion. The rise of e-commerce has heightened need for robust protective packaging to prevent damage during transit. In food and beverage, flexible pouches and resealable containers are favored for convenience and portion control. Healthcare applications demand vial caps, blister packs and sachets with precise dosing and sterility.

Plastic packaging encompasses a wide range of products including films, containers, bottles, closures and pouches made from materials such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), polypropylene (PP) and polystyrene (PS). These solutions offer light weight, exceptional barrier properties against moisture and oxygen, high durability, chemical resistance and ease of molding into complex shapes.

Plastic Packaging Market

https://www.coherentmarket...

#PlasticPackaging ,#SustainablePackaging,#EcoFriendlyPlastics,#BioBasedPolymers,

#PackagingInnovation ,#Coherentmarketinsights.

08:30 AM - May 24, 2025 (UTC)

Automotive Plastics Market Size Global Report | 2033

The global automotive plastics market size reached USD 44.1 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 62.6 Billion by 2033, exhibiting a growth rate (CAGR) of 3.77% during 2025-2033. Automotive plastics include polypropylene (PP), polyurethane (PU), polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), nylon, polyethylene (PE), polyoxymethylene (POM) and polycarbonate (PC). These plastics assist in extending the life of automobiles, increasing design flexibility, reducing manufacturing costs and easing integration of components.

Read More: https://www.imarcgroup.com...

The global automotive plastics market size reached USD 44.1 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 62.6 Billion by 2033, exhibiting a growth rate (CAGR) of 3.77% during 2025-2033. Automotive plastics include polypropylene (PP), polyurethane (PU), polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), nylon, polyethylene (PE), polyoxymethylene (POM) and polycarbonate (PC). These plastics assist in extending the life of automobiles, increasing design flexibility, reducing manufacturing costs and easing integration of components.

Read More: https://www.imarcgroup.com...

01:25 PM - May 29, 2025 (UTC)