Ship Conversion: Transforming Maritime Assets for Enhanced Operational Efficiency and Sustainability

Understanding the Fundamentals of Ship Conversion

Ship Conversion represents a sophisticated engineering process that involves transforming a vessel's original design, structure, and functionality to meet specific operational needs. Unlike traditional shipbuilding, conversion allows shipowners and operators to reimagine existing assets, potentially extending their operational lifecycle and reducing capital expenditure.

Ship Conversion-https://www.writerscafe.or...

#ship Conversion,

#maritime Engineering,

#Economic Rationale,

#Strategic Planning,

#operational Capabilities,

#Coherent Market Insights

Understanding the Fundamentals of Ship Conversion

Ship Conversion represents a sophisticated engineering process that involves transforming a vessel's original design, structure, and functionality to meet specific operational needs. Unlike traditional shipbuilding, conversion allows shipowners and operators to reimagine existing assets, potentially extending their operational lifecycle and reducing capital expenditure.

Ship Conversion-https://www.writerscafe.or...

#ship Conversion,

#maritime Engineering,

#Economic Rationale,

#Strategic Planning,

#operational Capabilities,

#Coherent Market Insights

08:48 AM - Mar 25, 2025 (UTC)

Global Glucose Biosensor : Revolutionizing Diabetes Management and Healthcare Technologies

The fundamental architecture of Global Glucose Biosensor typically involves three primary components: a biological recognition element, a transducer, and an electronic signal processing system. Enzymatic reactions serve as the primary detection mechanism, converting biochemical interactions into measurable electrical signals. This intricate process allows for instantaneous and precise glucose level assessment, making these biosensors invaluable in diabetes management and medical monitoring.

Global Glucose Biosensor-https://www.coherentmarket...

#global Glucose Biosensor,

#HealthCare ,

#Cutting -Edge,

#Chronic Metabolic Disorders,

#Biological Recognition,

#Coherent Market Insights

The fundamental architecture of Global Glucose Biosensor typically involves three primary components: a biological recognition element, a transducer, and an electronic signal processing system. Enzymatic reactions serve as the primary detection mechanism, converting biochemical interactions into measurable electrical signals. This intricate process allows for instantaneous and precise glucose level assessment, making these biosensors invaluable in diabetes management and medical monitoring.

Global Glucose Biosensor-https://www.coherentmarket...

#global Glucose Biosensor,

#HealthCare ,

#Cutting -Edge,

#Chronic Metabolic Disorders,

#Biological Recognition,

#Coherent Market Insights

01:07 PM - Mar 20, 2025 (UTC)

Exploring the Benefits of Educational Tourism for Students and Travelers

Educational Tourism offers numerous advantages to students and learners of all ages. One of the key benefits is the opportunity for hands-on learning. Whether it's studying marine biology in the Great Barrier Reef or exploring the architecture of ancient cities in Italy, these experiences create deep, lasting impressions that textbooks alone cannot provide.

Educational Tourism-https://www.coherentmarket...

#EducationalTourism ,

#EducationSectors ,

#knowledge ,

#museums ,

#history ,

#CoherentMarketInsights

Educational Tourism offers numerous advantages to students and learners of all ages. One of the key benefits is the opportunity for hands-on learning. Whether it's studying marine biology in the Great Barrier Reef or exploring the architecture of ancient cities in Italy, these experiences create deep, lasting impressions that textbooks alone cannot provide.

Educational Tourism-https://www.coherentmarket...

#EducationalTourism ,

#EducationSectors ,

#knowledge ,

#museums ,

#history ,

#CoherentMarketInsights

12:17 PM - Mar 18, 2025 (UTC)

The Global Ultrasonic Aspirator Market is driven by enhancing surgical management using innovative technologies

The Global Ultrasonic Aspirator Market is estimated to be valued at US$ 180.2 Mn in 2024 and is expected to exhibit a CAGR of 6.5% over the forecast period 2024 to 2031.

The growing Ultrasonic Aspirator Market Demand for minimally invasive surgeries around the world is fueling the ultrasonic aspirator market. Technological advancements in surgical equipment have stimulated increased adoption of ultrasonic aspirators over conventional methods.

Ultrasonic Aspirator Market-

#Ultrasonic Aspirator, #Ultrasonic Aspirator Market,

#Ultrasonic Aspirator Market Growth,

#Ultrasonic Aspirator Market Share,

#Traditional Method,

#neurological Disorders,

#Coherent Market Insights

The Global Ultrasonic Aspirator Market is estimated to be valued at US$ 180.2 Mn in 2024 and is expected to exhibit a CAGR of 6.5% over the forecast period 2024 to 2031.

The growing Ultrasonic Aspirator Market Demand for minimally invasive surgeries around the world is fueling the ultrasonic aspirator market. Technological advancements in surgical equipment have stimulated increased adoption of ultrasonic aspirators over conventional methods.

Ultrasonic Aspirator Market-

#Ultrasonic Aspirator, #Ultrasonic Aspirator Market,

#Ultrasonic Aspirator Market Growth,

#Ultrasonic Aspirator Market Share,

#Traditional Method,

#neurological Disorders,

#Coherent Market Insights

Ultrasonic Aspirator Market is Estimated to Witness High Growth Owing to Technological Advancements in Surgical Procedures | by Pragatibcmi | Mar, 2025 | Medium

Ultrasonic aspirators are medical devices used in surgical procedures to fragment and aspirate soft tissues such as blood, emulsified fat and other debris. These devices fragment tissues using…

https://medium.com/@pragatibcmi/ultrasonic-aspirator-market-is-estimated-to-witness-high-growth-owing-to-technological-advancements-366daf4827b3

10:27 AM - Mar 17, 2025 (UTC)

The Global Ileostomy Market is driven by rising prevalence of bowel diseases

Global ileostomy market is estimated to be valued at USD 1.90 Bn in 2024 and is expected to reach USD 3.15 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 7.5% from 2024 to 2031

Growing demand: Rising incidence of ulcerative colitis, Crohn's disease and colon cancer cases around the world is a key factor driving the Global Ileostomy Market Demand for procedures and products. The growing elderly population also contributes to market growth.

Global Ileostomy Market-https://www.zupyak.com/p/4...

#global Ileostomy #global Ileostomy Market

#global Ileostomy Market Growth

#global Ileostomy Market Demand

#Hygienic

#skin Irritation

#Coherent Market Insights

Global ileostomy market is estimated to be valued at USD 1.90 Bn in 2024 and is expected to reach USD 3.15 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 7.5% from 2024 to 2031

Growing demand: Rising incidence of ulcerative colitis, Crohn's disease and colon cancer cases around the world is a key factor driving the Global Ileostomy Market Demand for procedures and products. The growing elderly population also contributes to market growth.

Global Ileostomy Market-https://www.zupyak.com/p/4...

#global Ileostomy #global Ileostomy Market

#global Ileostomy Market Growth

#global Ileostomy Market Demand

#Hygienic

#skin Irritation

#Coherent Market Insights

09:33 AM - Feb 13, 2025 (UTC)

Actinic Keratosis: What You Should Know About Its Risks and Treatment

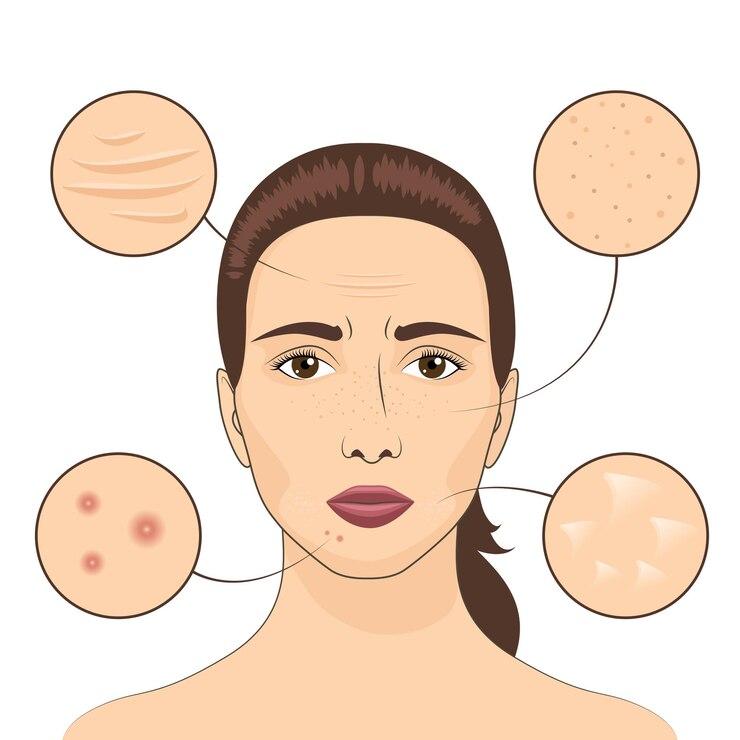

Symptoms and Appearance of Actinic Keratosis

The common signs and symptoms of Actinic Keratosis include scaly or crusty skin lesions that may be pink, skin-colored or brown in appearance. The lesions can range in size from less than 3 mm to over 10 mm and may feel rough, dry or thickened to the touch. The borders of individual AK lesions are generally indistinct and partially raised above normal skin level. Single lesions are common but multiple AK patches commonly develop in areas with long-term sun exposure. AK should be evaluated and treated as they can potentially worsen and become squamous cell carcinoma over time if left untreated.

Actinic Keratosis-https://www.coherentmarket...

#ActinicKeratosis #SkinHealth #SunDamage #UVProtection #NaturalSkincare #Dermatology #Coherent Market Insights

Symptoms and Appearance of Actinic Keratosis

The common signs and symptoms of Actinic Keratosis include scaly or crusty skin lesions that may be pink, skin-colored or brown in appearance. The lesions can range in size from less than 3 mm to over 10 mm and may feel rough, dry or thickened to the touch. The borders of individual AK lesions are generally indistinct and partially raised above normal skin level. Single lesions are common but multiple AK patches commonly develop in areas with long-term sun exposure. AK should be evaluated and treated as they can potentially worsen and become squamous cell carcinoma over time if left untreated.

Actinic Keratosis-https://www.coherentmarket...

#ActinicKeratosis #SkinHealth #SunDamage #UVProtection #NaturalSkincare #Dermatology #Coherent Market Insights

12:23 PM - Feb 11, 2025 (UTC)

The Role of Waterborne Adhesives in Automotive Manufacturing

Waterborne Adhesives play an essential role in automotive manufacturing, where strong, reliable, and environmentally friendly bonding solutions are critical. These adhesives are used throughout the production of automobiles, from assembly to finishing, providing effective solutions for bonding various materials, including metals, plastics, glass, and textiles.

One of the key benefits of Waterborne Adhesives in the automotive industry is their environmental safety. Traditional adhesives often contain solvents that release harmful volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and posing health risks to workers.

Waterborne Adhesives-https://www.coherentmarket...

#Waterborne Adhesives #Primary Solvent

#Emulsions #polymer #Eco -Friendly

#Stabilizer #Coherent Market Insights

Waterborne Adhesives play an essential role in automotive manufacturing, where strong, reliable, and environmentally friendly bonding solutions are critical. These adhesives are used throughout the production of automobiles, from assembly to finishing, providing effective solutions for bonding various materials, including metals, plastics, glass, and textiles.

One of the key benefits of Waterborne Adhesives in the automotive industry is their environmental safety. Traditional adhesives often contain solvents that release harmful volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and posing health risks to workers.

Waterborne Adhesives-https://www.coherentmarket...

#Waterborne Adhesives #Primary Solvent

#Emulsions #polymer #Eco -Friendly

#Stabilizer #Coherent Market Insights

10:07 AM - Feb 11, 2025 (UTC)

Cochlear Implants and Children: Enhancing Early Language Development

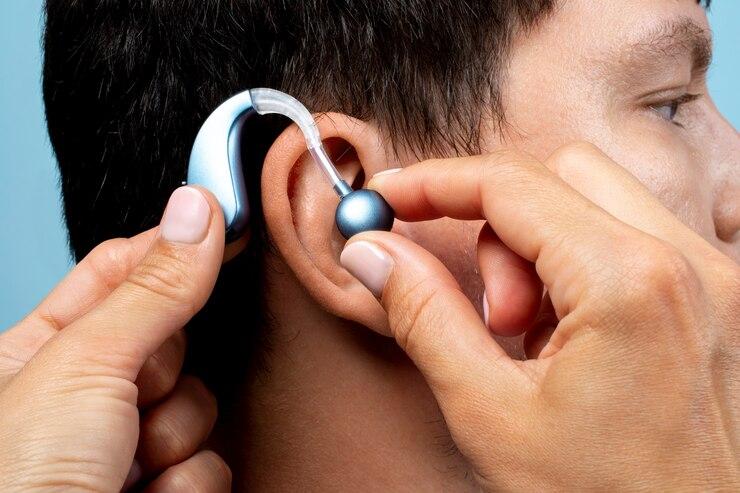

After surgery, the child’s Cochlear Implants is activated, and auditory training begins. Speech therapists work with the child to help them process the new sounds they are hearing. This process can take time, and the child’s progress will be closely monitored to ensure the implant is working as effectively as possible. Over time, with the right support, many children with Cochlear Implants can learn to speak, understand language, and interact socially with their peers.

Cochlear Implants-https://www.coherentmarket...

#Cochlear Implants #medical Devices #Hearing Loss #Hearing Aids #AuditoryNerve #Microphone #brain ,

#Coherent Market Insights

After surgery, the child’s Cochlear Implants is activated, and auditory training begins. Speech therapists work with the child to help them process the new sounds they are hearing. This process can take time, and the child’s progress will be closely monitored to ensure the implant is working as effectively as possible. Over time, with the right support, many children with Cochlear Implants can learn to speak, understand language, and interact socially with their peers.

Cochlear Implants-https://www.coherentmarket...

#Cochlear Implants #medical Devices #Hearing Loss #Hearing Aids #AuditoryNerve #Microphone #brain ,

#Coherent Market Insights

07:30 AM - Feb 11, 2025 (UTC)

How to Navigate the Stages of a Product Lifecycle Management for Maximum Impact

All products go through distinct phases from the time of their conception to the point of being withdrawn from the market. Knowing the typical stages that define a product's lifecycle helps organizations optimize resources and plan for changes at each phase. This article explores the key stages in a product's journey and discusses what takes place during each.

Product Lifecycle Management-https://www.zupyak.com/p/4...

#ProductLifecycleManagement ,

#productdevelopment ,

#MarketGrowthStrategy ,

#ProductLaunch ,

#ProductMaturity ,

#MarketSaturation ,

#ProductDecline ,

#CoherentMarketInsights

All products go through distinct phases from the time of their conception to the point of being withdrawn from the market. Knowing the typical stages that define a product's lifecycle helps organizations optimize resources and plan for changes at each phase. This article explores the key stages in a product's journey and discusses what takes place during each.

Product Lifecycle Management-https://www.zupyak.com/p/4...

#ProductLifecycleManagement ,

#productdevelopment ,

#MarketGrowthStrategy ,

#ProductLaunch ,

#ProductMaturity ,

#MarketSaturation ,

#ProductDecline ,

#CoherentMarketInsights

02:21 PM - Feb 07, 2025 (UTC)

Understanding Hair Loss: Key Causes and Effective Treatment Paths

Genetics is a major cause of hereditary hair loss. This type of hair loss is called androgenetic alopecia or male/female pattern baldness. In men, it presents as thinning hair on the frontal scalp area and vertex (top of the head). In women, it may present as generalized thinning over the top of the scalp. About 50% of men begin losing their hair by age 50. Genetics determine hair follicle sensitivity to dihydrotestosterone (DHT), a hormone derived from testosterone. DHT binding to hair follicles reduces their size and life span over time.

Hair Loss Treatment-https://www.coherentmarket...

#HairLossTreatment ,

#MalePatternBaldness ,

#DHT ,

#AndrogenicAlopecia ,

#Finasteride ,

#Minoxidil ,

#Coherent Market Insights

Genetics is a major cause of hereditary hair loss. This type of hair loss is called androgenetic alopecia or male/female pattern baldness. In men, it presents as thinning hair on the frontal scalp area and vertex (top of the head). In women, it may present as generalized thinning over the top of the scalp. About 50% of men begin losing their hair by age 50. Genetics determine hair follicle sensitivity to dihydrotestosterone (DHT), a hormone derived from testosterone. DHT binding to hair follicles reduces their size and life span over time.

Hair Loss Treatment-https://www.coherentmarket...

#HairLossTreatment ,

#MalePatternBaldness ,

#DHT ,

#AndrogenicAlopecia ,

#Finasteride ,

#Minoxidil ,

#Coherent Market Insights

11:09 AM - Feb 07, 2025 (UTC)

Sponsored by

OWT

5 months ago

Dwngo social network website

Dwngo – The Social Media Platform! * Share your thoughts & ideas * Publish blogs & trending stories * Connect, engage & grow your networkJoin now & be part of the future of social networking! #SocialMedia #Blogging #Dwngo --https://dwngo.com/