Undergoing a diesel engine overhaul can significantly enhance your vehicle's fuel efficiency. As engines age, accumulated wear and tear can cause them to work harder, consuming more fuel. An overhaul addresses issues such as worn-out piston rings, clogged fuel injectors, and faulty valves, restoring the engine's original efficiency. This process not only improves fuel economy but also extends the engine's lifespan, ensuring smoother operation and reduced maintenance costs. Investing in regular overhauls keeps your diesel engine performing at its best, offering both economic and environmental benefits.

For more information visit here- https://mpapowerproject.in...

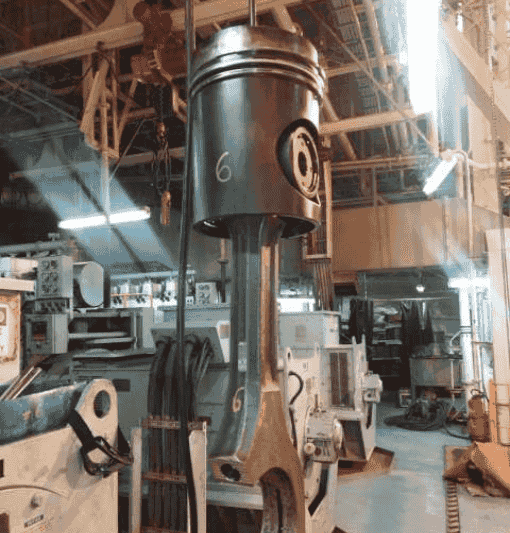

Reliable Repair and Overhaul of Engines

MPA Power Project specializes in repair and overhaul of engines, delivering quality service to keep your marine and industrial engines running smoothly.

https://mpapowerproject.in/services/repair-and-overhaul-of-engines/Experiencing engine vibrations or performance issues? In-situ Grinding of Crankshaft is the ideal solution to restore your crankshaft without costly dismantling. This process ensures precise grinding, correcting wear, misalignment, and damage while minimizing downtime. MPA Power Project specializes in In-situ Grinding of Crankshaft, delivering high-quality repairs for marine, industrial, and power plant engines. Our expert team ensures smooth engine operations, enhancing efficiency and reliability. Don’t let a damaged crankshaft slow you down—reach out to us for professional on-site repairs that save time and costs.

For more information visit here- https://mpapowerproject.in...

In-situ grinding is a cutting-edge solution for crankshaft repair, allowing maintenance without removing the crankshaft from the engine. This method uses portable equipment to grind and restore crankshaft surfaces, saving time and reducing equipment downtime. It eliminates the need for costly disassembly and transportation, making it a cost-effective maintenance approach. Industries relying on heavy machinery benefit from this technique as it extends the crankshaft's lifespan and enhances operational efficiency. Learn more about the advantages of in-situ grinding in modern engine maintenance.

For more information visit here- https://mpapowerproject.in...

How In-situ Grinding Saves Your Crankshaft Without Disassembly

Save time & costs with in-situ grinding! Onsite crankshaft repair eliminates disassembly, minimizes downtime & restores engine performance.

https://mpapowerproject.in/how-in-situ-grinding-saves-crankshaft/Maximizing the lifespan of your crankshaft is crucial for maintaining engine efficiency and performance. In-situ grinding offers a cost-effective and efficient solution by repairing and restoring crankshafts without the need for complete disassembly. This process reduces downtime, minimizes costs, and ensures precision in grinding, helping to prevent further damage and extend the crankshaft’s operational life.

Whether for marine engines, industrial machinery, or power plants, in-situ grinding is a reliable method to enhance durability and performance. For more information, please read the full blog post “Extending Crankshaft Life: Benefits of In-Situ Grinding”.

For more information please visit here https://mpapowerprojectseo...

In-situ grinding of crankshafts is a game-changer for marine engine repair, offering a cost-effective and time-saving alternative to traditional repair methods. This process eliminates the need to dismantle the crankshaft, reducing downtime and operational costs significantly. Ideal for ships and power plants, in-situ grinding ensures precise restoration of crankshaft journals, enhancing engine performance and longevity.

Whether dealing with wear, damage, or misalignment, this method delivers high-quality results without the hassle of engine disassembly. For more information, please read the full blog post “In-Situ Grinding of Crankshafts: Solution for Marine Engine Repair”.

For more information please visit here https://mpapowerproject.in...

In-Situ Grinding of Crankshafts: Effective Marine Engine Repair

The benefits of in-situ grinding of crankshafts—a cost-effective solution for marine engine repair, reducing downtime and maintenance costs.

https://mpapowerproject.in/in-situ-grinding-crankshafts-cost-effective-marine-engine-repair/Dwngo social network website

Dwngo – The Social Media Platform! * Share your thoughts & ideas * Publish blogs & trending stories * Connect, engage & grow your networkJoin now & be part of the future of social networking! #SocialMedia #Blogging #Dwngo --https://dwngo.com/