Metal Injection Molding has become the standard choice for industries requiring high volume production of precise, consistent, complex metal pieces with very tight tolerances. Every stage of the MIM process right from feedstock preparation to final sintering is influenced by the characteristics of Metal Injection Molding Material Properties. For more details, please visit :- https://mimsupplierus.blog...

Metal Injection Molding Material Properties: Increase Your Product’s Performance

Metal Injection Molding has become the standard choice for industries requiring high volume production of precise, consistent, complex metal...

https://mimsupplierus.blogspot.com/2025/05/metal-injection-molding-material.htmlThe mold for MIM has a large influence on the product dimensional capability during production. Once the component is ejected from the tool there remains little capability to adjust dimensions except with extra cost. MIM tooling looks similar to that used in plastic injection molding, although molds are oversized to account for the large sintering shrinkage. For more details, please visit :- https://mim-supplier.com/b...

Precautions for MIM Manufacturing – MIM Supplier

The mold for MIM has a large influence on the product dimensional capability during production. Once the component is ejected from the tool there remains little capability to adjust dimensions except with extra cost. MIM tooling looks similar to that used in plastic injection molding, although molds..

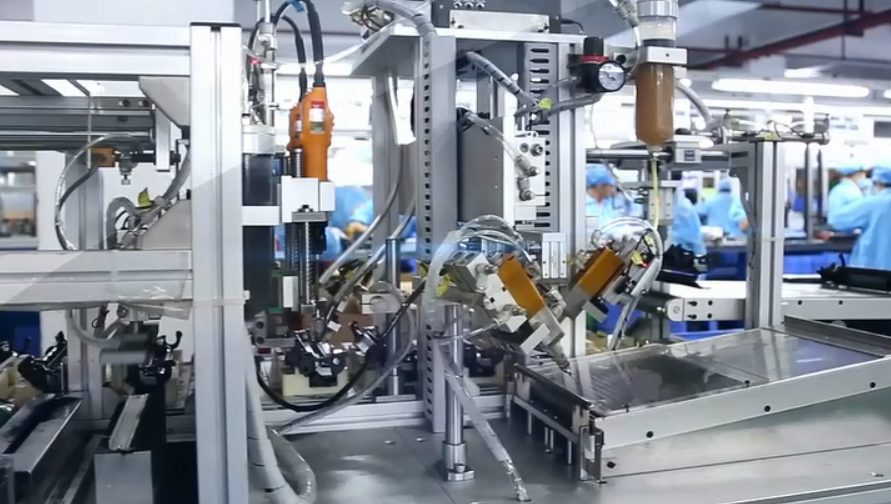

https://mim-supplier.com/blogs/knowledge/precautions-for-mim-manufacturingMetal Injection Molding uses a brilliant innovative technique to blend the benefits of plastic injection molding with the strength and integrity of metal to produce complex parts. Industries such as automotive, medical, aerospace and more are choosing a right Metal Injection Molding Parts Company. For more details, please visit :- https://mimsupplierus.blog...

Metal Injection Molding Parts Company: Produce Complex Components with Precision

Today, there is a big demand for precision in manufacturing. In the last decade, the demand for high performance, cost-effective and complex...

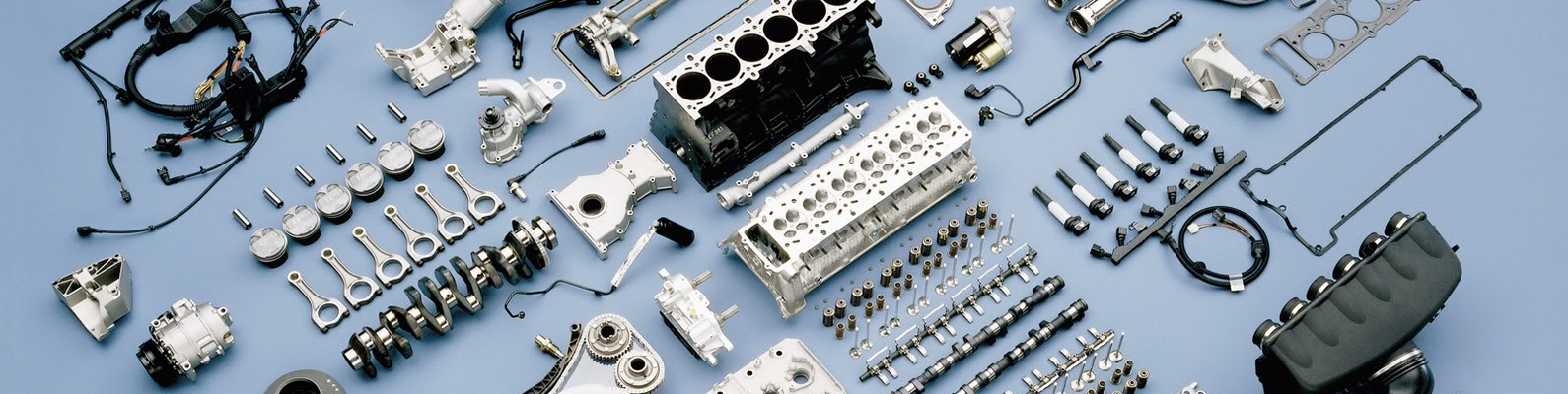

https://mimsupplierus.blogspot.com/2025/04/metal-injection-molding-parts-company.htmlThis area of research is applicable to powder metallurgy in water manufacture. It develops high-performance components that are inexpensive and lightweight; that is, it achieves high efficiency by producing advanced powder processes in metal form. For more details, please visit :- https://mimsupplierus.word...

Powder Metallurgy in Automotive Applications: Revolutionizing Vehicle Manufacturing – XY Electronics Technology Co., Ltd

This area of research is applicable to powder metallurgy in water manufacture. It develops high-performance components that are inexpensive and lightweight; that is, it achieves high efficiency by producing advanced powder processes in metal form. Metal powder is preferably made through consolidatio..

https://mimsupplierus.wordpress.com/2025/04/30/powder-metallurgy-in-automotive-applications-revolutionizing-vehicle-manufacturing/🔹 Intricate geometries

🔹 High material density

🔹 Consistent batch production

🔹 Custom solutions available

Explore how MIM can elevate your next product.

#MetalInjectionMolding #MIMParts #PrecisionManufacturing #CustomComponents #XYGlobal

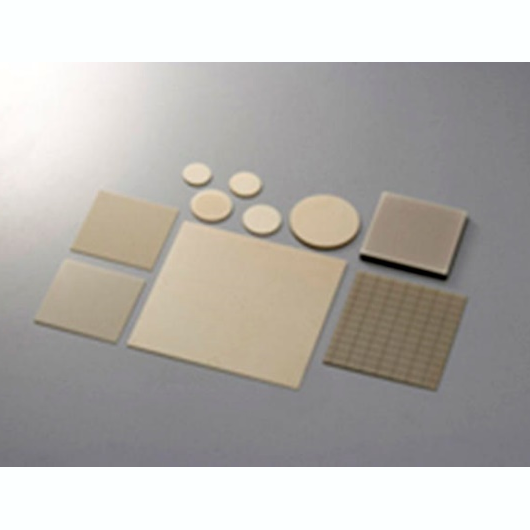

Metal Injection Moulding (MIM) is a suitable technology to fabricate small or medium-sized pieces with complex geometry. A variety of materials can be used (stainless steels, low-alloy steels, soft magnetic, tooling steel or ceramic materials). For more details, please visit :- https://mim-supplier.com/b...

How to Use Mim in the Production of Metal Parts – MIM Supplier

Metal Injection Moulding (MIM) is a suitable technology to fabricate small or medium-sized pieces with complex geometry. A variety of materials can be used (stainless steels, low-alloy steels, soft magnetic, tooling steel or ceramic materials). MIM combines the technique and versatility of plastic i..

https://mim-supplier.com/blogs/knowledge/how-to-use-mim-in-the-production-of-metal-partsYou’ve probably heard all about the benefits of 3D printing for rapid prototyping. But did you know that many companies are now using additive manufacturing for mass production? For more details, please visit :- https://mim-supplier.com/b...

Using Metal Additive Manufacturing for Mass Production – MIM Supplier

You’ve probably heard all about the benefits of 3D printing for rapid prototyping. But did you know that many companies are now using additive manufacturing for mass production? While rapid prototyping is still a part of the game, it’s quickly being replaced with the knowledge that metal additiv..

https://mim-supplier.com/blogs/knowledge/using-metal-additive-manufacturing-for-mass-productionLooking for reliable metal injection molding aluminum manufacturers? MIM Supplier delivers advanced MIM solutions for lightweight, high-strength aluminum components. For more details, please visit :- https://mim-supplier.com/c...

Get high-precision MIM medical parts designed for durability and biocompatibility. MIM Supplier specializes in metal injection molding solutions for surgical instruments and medical devices. For more details, please visit :- https://mim-supplier.com/c...

XY Electronics Technology Co., Ltd specializes in Customized Metal Injection Molding (MIM), delivering high-precision, complex metal parts tailored to aerospace, medical, and automotive needs with superior strength, durability, and cost-effective manufacturing solutions. For more information visit us at: https://mim-supplier.com/p...

Dwngo social network website

Dwngo – The Social Media Platform! * Share your thoughts & ideas * Publish blogs & trending stories * Connect, engage & grow your networkJoin now & be part of the future of social networking! #SocialMedia #Blogging #Dwngo --https://dwngo.com/