11:45 AM - May 02, 2025 (UTC)

DIN 2615 Buttweld Pipe Fittings are high-quality fittings used for connecting pipes in industrial applications. These fittings are manufactured according to the Deutsches Institut für Normung (DIN) 2615 standard and are primarily used for changing the direction of flow in piping systems. They are widely utilized in industries such as oil & gas, petrochemicals, power plants, and shipbuilding.

Types of DIN 2615 Buttweld Pipe Fittings:

DIN 2615-1 (Concentric Tee) – Used to equally distribute the flow of fluids.

DIN 2615-2 (Eccentric Tee) – Ideal for applications requiring an offset between the branch and run pipe.

Read More

https://emirerristeel.com/...

Types of DIN 2615 Buttweld Pipe Fittings:

DIN 2615-1 (Concentric Tee) – Used to equally distribute the flow of fluids.

DIN 2615-2 (Eccentric Tee) – Ideal for applications requiring an offset between the branch and run pipe.

Read More

https://emirerristeel.com/...

11:03 AM - Mar 03, 2025 (UTC)

(E)

Explore premium-grade AWWA C207 Flanges in Classes B, D, E, and F by Emirerri Steel. Engineered to meet stringent AWWA standards, these flanges are perfect for waterworks, wastewater systems, and industrial piping applications.

Our flanges are manufactured with precision to deliver exceptional durability, corrosion resistance, and reliable performance under varying pressure ratings. Available in multiple materials and customizable dimensions, they cater to diverse project needs.

Choose Emirerri Steel for top-quality, certified AWWA C207 Flanges and elevate your piping systems’ efficiency. Contact us today for tailored solutions!

#SteelIndustry #SteelProducts #SteelManufacturing #flange #awwac207 #awwacc207flange

Our flanges are manufactured with precision to deliver exceptional durability, corrosion resistance, and reliable performance under varying pressure ratings. Available in multiple materials and customizable dimensions, they cater to diverse project needs.

Choose Emirerri Steel for top-quality, certified AWWA C207 Flanges and elevate your piping systems’ efficiency. Contact us today for tailored solutions!

#SteelIndustry #SteelProducts #SteelManufacturing #flange #awwac207 #awwacc207flange

07:56 AM - Dec 31, 2024 (UTC)

Emirerri Steel offers a wide range of high-strength structural steel plates, designed to meet the demanding requirements of modern construction and engineering projects. Our plates are manufactured to provide superior strength, durability, and versatility, making them ideal for various applications in the construction, automotive, and heavy machinery industries.

https://emirerristeel.com/...

https://emirerristeel.com/...

07:01 AM - Aug 28, 2024 (UTC)

At Emirerri Steel, we specialize in providing top-tier wear resistant steel plates designed to withstand the toughest conditions. Our wear resistant steel plates are engineered to offer exceptional hardness, strength, and durability, making them the ideal choice for industries requiring materials that can endure extreme wear and tear.

https://emirerristeel.com/...

https://emirerristeel.com/...

06:45 AM - Aug 24, 2024 (UTC)

Ship Building Steel Plate - Emirerristeel

Emirerri Steel offers premium quality Ship Building Steel Plates, designed to meet the rigorous demands of the maritime industry. These plates are manufactured from high-grade steel, ensuring exceptional strength, durability, and resistance to harsh marine environments.

Key Features:

High Strength: Exceptional tensile and yield strength for robust and reliable performance in demanding marine applications.

Corrosion Resistance: Enhanced resistance to seawater and atmospheric corrosion, ensuring longevity and reduced maintenance costs.

Weldability: Excellent weldability allows for easy fabrication and assembly, minimizing production time and costs.

Toughness: Superior toughness to withstand extreme conditions and impact, ensuring safety and structural integrity.

Compliance: Meets or exceeds international standards, including ABS, LR, DNV, and more, ensuring global acceptance and reliability.

https://emirerristeel.com/...

Emirerri Steel offers premium quality Ship Building Steel Plates, designed to meet the rigorous demands of the maritime industry. These plates are manufactured from high-grade steel, ensuring exceptional strength, durability, and resistance to harsh marine environments.

Key Features:

High Strength: Exceptional tensile and yield strength for robust and reliable performance in demanding marine applications.

Corrosion Resistance: Enhanced resistance to seawater and atmospheric corrosion, ensuring longevity and reduced maintenance costs.

Weldability: Excellent weldability allows for easy fabrication and assembly, minimizing production time and costs.

Toughness: Superior toughness to withstand extreme conditions and impact, ensuring safety and structural integrity.

Compliance: Meets or exceeds international standards, including ABS, LR, DNV, and more, ensuring global acceptance and reliability.

https://emirerristeel.com/...

09:47 AM - Aug 23, 2024 (UTC)

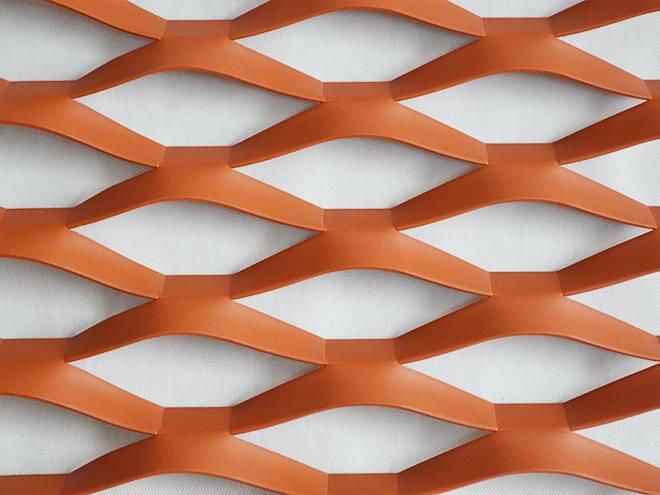

Decorative Expanded Metal - Emirerristeel

Decorative Expanded Metal is a versatile and aesthetically pleasing material created by slitting and stretching metal sheets into a variety of intricate patterns. This process results in a durable and lightweight mesh with unique designs, making it ideal for architectural and design applications. Decorative Expanded Metal combines functionality with visual appeal, offering solutions for both interior and exterior projects.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

Custom Patterns

https://emirerristeel.com/...

Decorative Expanded Metal is a versatile and aesthetically pleasing material created by slitting and stretching metal sheets into a variety of intricate patterns. This process results in a durable and lightweight mesh with unique designs, making it ideal for architectural and design applications. Decorative Expanded Metal combines functionality with visual appeal, offering solutions for both interior and exterior projects.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

Custom Patterns

https://emirerristeel.com/...

10:40 AM - Aug 22, 2024 (UTC)

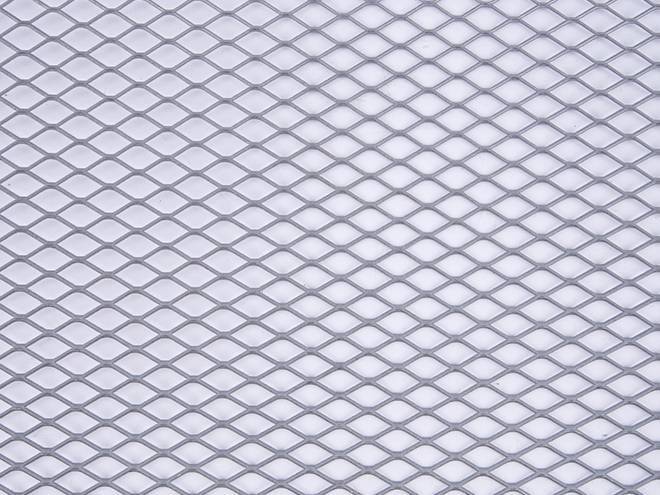

Small Hole Expanded Metal - Emirerristeel

Small Hole Expanded Metal is a versatile material created by slitting and stretching metal sheets into a fine mesh with small openings. The resulting product offers excellent precision, durability, and versatility, making it ideal for applications requiring fine filtration, screening, ventilation, and decorative purposes. It is available in various materials, including carbon steel, stainless steel, aluminum, and galvanized steel, and can be customized in terms of hole size, strand width, thickness, and surface treatments to meet specific requirements.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

https://emirerristeel.com/...

Small Hole Expanded Metal is a versatile material created by slitting and stretching metal sheets into a fine mesh with small openings. The resulting product offers excellent precision, durability, and versatility, making it ideal for applications requiring fine filtration, screening, ventilation, and decorative purposes. It is available in various materials, including carbon steel, stainless steel, aluminum, and galvanized steel, and can be customized in terms of hole size, strand width, thickness, and surface treatments to meet specific requirements.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

https://emirerristeel.com/...

10:35 AM - Aug 21, 2024 (UTC)

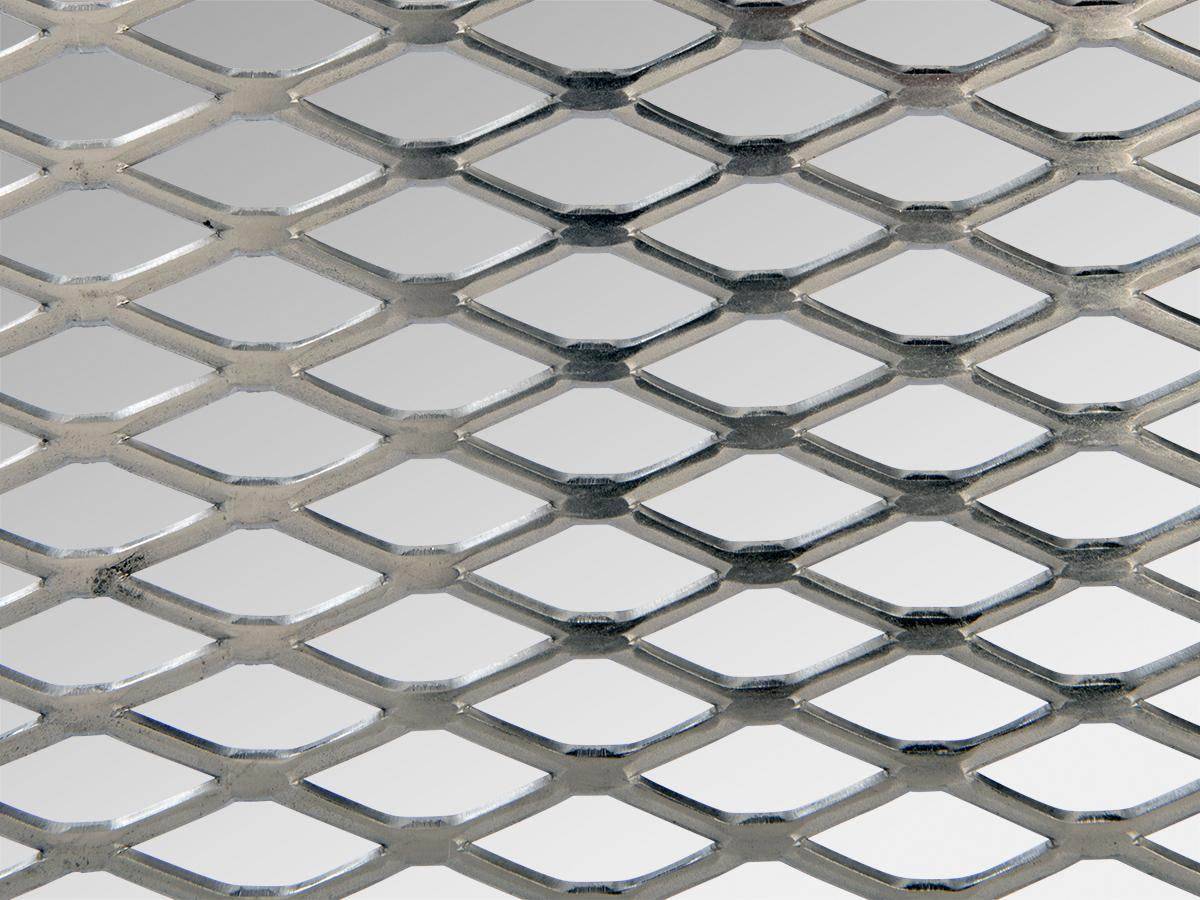

Expanded Metal Grating - Emirerristeel

Expanded Metal Grating is a durable and versatile structural material formed by expanding and flattening metal sheets to create a grid-like pattern with diamond-shaped openings. This process enhances its strength-to-weight ratio, making it ideal for applications requiring robust load-bearing capabilities and excellent ventilation. Expanded Metal Grating is widely used in industrial settings for walkways, platforms, stair treads, catwalks, ramps, and drainage covers.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

Micro Expanded Pattern

https://emirerristeel.com/...

Expanded Metal Grating is a durable and versatile structural material formed by expanding and flattening metal sheets to create a grid-like pattern with diamond-shaped openings. This process enhances its strength-to-weight ratio, making it ideal for applications requiring robust load-bearing capabilities and excellent ventilation. Expanded Metal Grating is widely used in industrial settings for walkways, platforms, stair treads, catwalks, ramps, and drainage covers.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

Micro Expanded Pattern

https://emirerristeel.com/...

11:20 AM - Aug 20, 2024 (UTC)

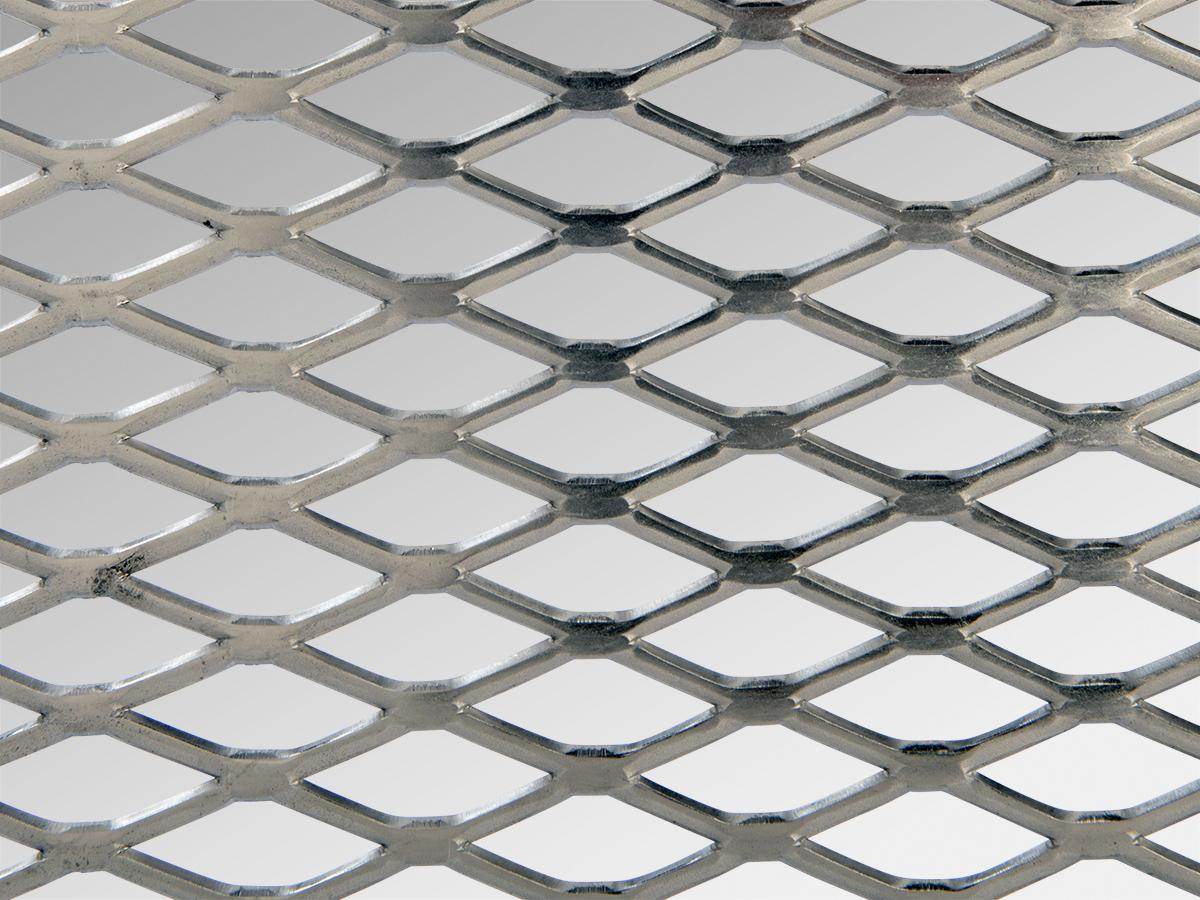

Flattened Expanded Metal - Emirerristeel

Flattened Expanded Metal is produced by taking standard expanded metal and passing it through a cold rolling mill to flatten the strands and bonds, resulting in a smooth, even surface. This process enhances the material’s appearance, makes it easier to handle, and provides a uniform thickness. Flattened Expanded Metal is highly versatile and suitable for a wide range of applications, including fencing, security screens, grating, walkways, platforms, architectural facades, machine guards, and decorative panels.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

Micro Expanded Pattern

https://emirerristeel.com/...

Flattened Expanded Metal is produced by taking standard expanded metal and passing it through a cold rolling mill to flatten the strands and bonds, resulting in a smooth, even surface. This process enhances the material’s appearance, makes it easier to handle, and provides a uniform thickness. Flattened Expanded Metal is highly versatile and suitable for a wide range of applications, including fencing, security screens, grating, walkways, platforms, architectural facades, machine guards, and decorative panels.

Hole Patterns:

Diamond Pattern

Hexagonal Pattern

Square Pattern

Round Pattern

Micro Expanded Pattern

https://emirerristeel.com/...

08:21 AM - Aug 16, 2024 (UTC)

(E)

Sponsored by

OWT

5 months ago

Dwngo social network website

Dwngo – The Social Media Platform! * Share your thoughts & ideas * Publish blogs & trending stories * Connect, engage & grow your networkJoin now & be part of the future of social networking! #SocialMedia #Blogging #Dwngo --https://dwngo.com/