Exploring the Future of the Extrusion Coating Market: Trends, Growth & Insights

Market Size and Forecast Outlook

The value of the Global Extrusion Coating Market is expected to increase from US$5,978.63 million in 2025 to US$9,578.46 million by 2035. From 2025 to 2035, the market is anticipated to grow at a CAGR of 4.8%. The growing need for sustainable and flexible packaging solutions across a range of industries is propelling the expansion of the global extrusion coating market.

Request Sample Copy:https://wemarketresearch.c...

The Extrusion Coating Market is poised for remarkable transformation over the next decade, fueled by rising demand across packaging, automotive, construction, and consumer goods industries. As global industries look for cost-effective, efficient, and environmentally sustainable coating solutions, extrusion coating has emerged as a game-changing technology. This blog offers an in-depth look at the Extrusion Coating Market Size, Extrusion Coating Market Share, Growth, Trends, and much more—delivering essential insights for investors, manufacturers, and market enthusiasts alike.

Market Size and Forecast Outlook

The value of the Global Extrusion Coating Market is expected to increase from US$5,978.63 million in 2025 to US$9,578.46 million by 2035. From 2025 to 2035, the market is anticipated to grow at a CAGR of 4.8%. The growing need for sustainable and flexible packaging solutions across a range of industries is propelling the expansion of the global extrusion coating market.

Request Sample Copy:https://wemarketresearch.c...

The Extrusion Coating Market is poised for remarkable transformation over the next decade, fueled by rising demand across packaging, automotive, construction, and consumer goods industries. As global industries look for cost-effective, efficient, and environmentally sustainable coating solutions, extrusion coating has emerged as a game-changing technology. This blog offers an in-depth look at the Extrusion Coating Market Size, Extrusion Coating Market Share, Growth, Trends, and much more—delivering essential insights for investors, manufacturers, and market enthusiasts alike.

06:08 AM - Jun 09, 2025 (UTC)

Aluminum Trailer Market to Skyrocket on Lightweight Design Demand

Growing Aluminum Trailer Market Demand for fuel-efficient transport solutions and lightweight equipment is reshaping market dynamics. End users across commercial fleets and recreational sectors increasingly prioritize aluminum trailers for their lower operating costs and enhanced payload capabilities. This shift drives market growth, business growth strategies, and spurs further investment in capacity expansion to meet rising market demand.

Aluminum trailers serve a broad spectrum of hauling applications—from cargo transport and livestock movement to recreational vehicle towing—thanks to their exceptional strength-to-weight ratio, corrosion resistance, and low maintenance requirements. Compared to steel counterparts, aluminum trailers deliver improved fuel efficiency, reduced vehicle wear, and enhanced payload capacity, driving adoption across logistics, agriculture, and leisure industries. Manufacturers leverage advanced extrusion techniques and precision welding to produce durable yet lightweight frames that address market challenges such as rising fuel costs and stringent emissions regulations.

Aluminum Trailer Market

https://www.coherentmarket...

#AluminuTrailers ,#LightweightTransport #FleetEfficiency #SmartLogistics #SustainableMobility

Growing Aluminum Trailer Market Demand for fuel-efficient transport solutions and lightweight equipment is reshaping market dynamics. End users across commercial fleets and recreational sectors increasingly prioritize aluminum trailers for their lower operating costs and enhanced payload capabilities. This shift drives market growth, business growth strategies, and spurs further investment in capacity expansion to meet rising market demand.

Aluminum trailers serve a broad spectrum of hauling applications—from cargo transport and livestock movement to recreational vehicle towing—thanks to their exceptional strength-to-weight ratio, corrosion resistance, and low maintenance requirements. Compared to steel counterparts, aluminum trailers deliver improved fuel efficiency, reduced vehicle wear, and enhanced payload capacity, driving adoption across logistics, agriculture, and leisure industries. Manufacturers leverage advanced extrusion techniques and precision welding to produce durable yet lightweight frames that address market challenges such as rising fuel costs and stringent emissions regulations.

Aluminum Trailer Market

https://www.coherentmarket...

#AluminuTrailers ,#LightweightTransport #FleetEfficiency #SmartLogistics #SustainableMobility

07:32 AM - May 16, 2025 (UTC)

What is MFI value and why is it important?

MFI value, or Melt Flow Index, is a key parameter in the plastics industry used to measure the ease of flow of melted thermoplastic materials. It is expressed in grams per 10 minutes and is determined by measuring how much polymer extrudes through a die under specific heat and pressure conditions.

This value helps manufacturers assess the processability of plastic materials during molding and extrusion. A higher MFI indicates lower viscosity and easier flow, which is crucial for thin-walled or detailed components. Conversely, a lower MFI suggests higher strength and toughness.

Understanding MFI is essential in selecting the right material for specific applications, ensuring consistent quality, and meeting production efficiency. It’s a vital test for quality control in plastic manufacturing. Contact us at +91 9210 903 903 or infoprestogroup.com for premium quality testing instruments tailored to your needs.

For more information visit our website:- https://www.prestogroup.co...

MFI value, or Melt Flow Index, is a key parameter in the plastics industry used to measure the ease of flow of melted thermoplastic materials. It is expressed in grams per 10 minutes and is determined by measuring how much polymer extrudes through a die under specific heat and pressure conditions.

This value helps manufacturers assess the processability of plastic materials during molding and extrusion. A higher MFI indicates lower viscosity and easier flow, which is crucial for thin-walled or detailed components. Conversely, a lower MFI suggests higher strength and toughness.

Understanding MFI is essential in selecting the right material for specific applications, ensuring consistent quality, and meeting production efficiency. It’s a vital test for quality control in plastic manufacturing. Contact us at +91 9210 903 903 or infoprestogroup.com for premium quality testing instruments tailored to your needs.

For more information visit our website:- https://www.prestogroup.co...

07:14 AM - May 15, 2025 (UTC)

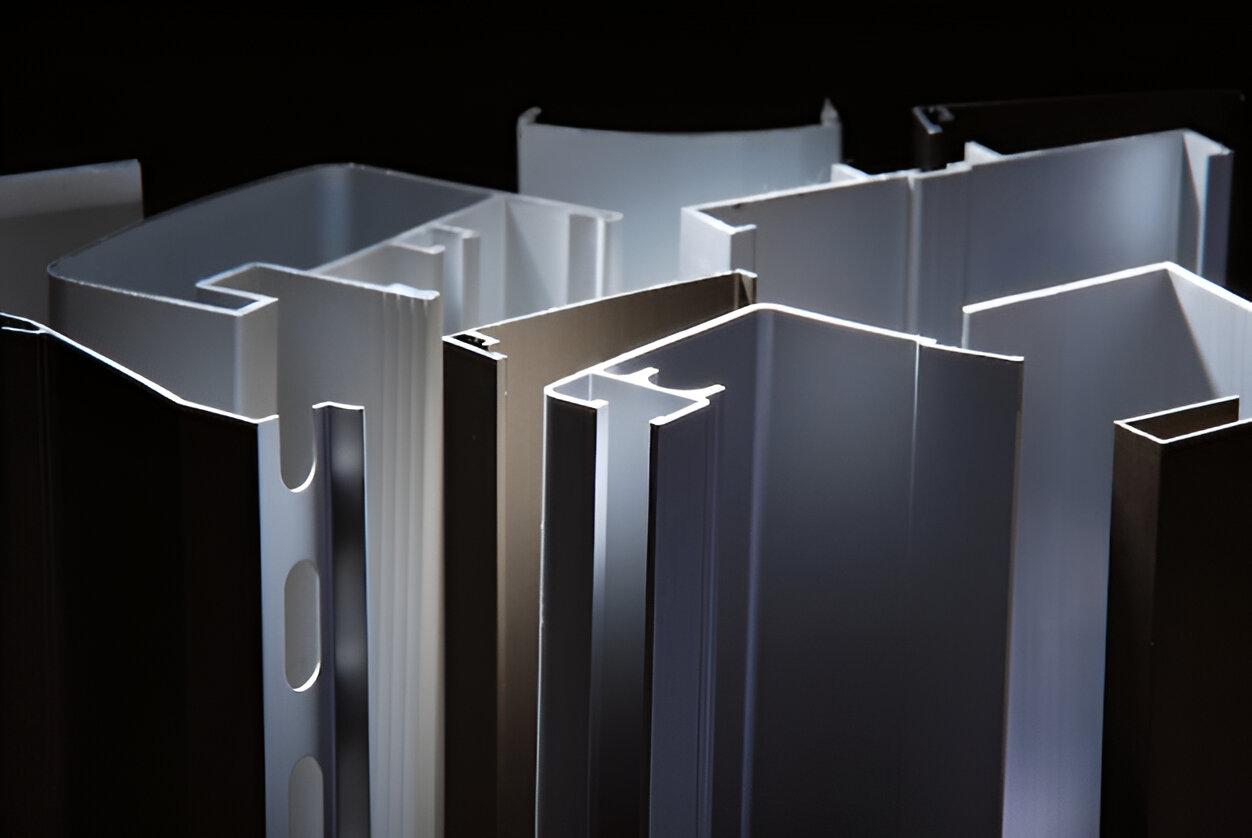

Aluminium Extrusion Sydney

https://aksharindustries.c...

Discover top-quality aluminium extrusion in Sydney with Akshar Industries. We specialise in durable and versatile extrusion products tailored for various applications. Trust us for precision and exceptional service—contact us today!

#aluminiumextrusionsydney

https://aksharindustries.c...

Discover top-quality aluminium extrusion in Sydney with Akshar Industries. We specialise in durable and versatile extrusion products tailored for various applications. Trust us for precision and exceptional service—contact us today!

#aluminiumextrusionsydney

09:26 AM - Jun 12, 2025 (UTC)

Melt Flow Index Tester

The Melt Flow Index Tester from Perfect Group India finds the flow rate of molten plastic under specific conditions. It guarantees reliable manufacturing by helping businesses to measure the quality, viscosity and melt strength of polymers. For injection molding, extrusion, and other plastic manufacturing processes, this tester is important to measuring the processing capacity of raw plastic materials, improving product quality, reducing waste and following industry standards.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial

The Melt Flow Index Tester from Perfect Group India finds the flow rate of molten plastic under specific conditions. It guarantees reliable manufacturing by helping businesses to measure the quality, viscosity and melt strength of polymers. For injection molding, extrusion, and other plastic manufacturing processes, this tester is important to measuring the processing capacity of raw plastic materials, improving product quality, reducing waste and following industry standards.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial

11:21 AM - May 12, 2025 (UTC)

Melt Flow Index Tester

The Melt Flow Index Tester measures the flow rate of melted thermoplastic polymers to analyze their suitability for various uses. It plays an important role in quality control and process optimization. Perfect Group India provides this advanced equipment designed for easy use and accurate performance. It helps manufacturers compare material grades and project behavior during molding or extrusion. Accurate results and strong construction make it important for the plastic, automotive and packaging industries.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial #equipment

The Melt Flow Index Tester measures the flow rate of melted thermoplastic polymers to analyze their suitability for various uses. It plays an important role in quality control and process optimization. Perfect Group India provides this advanced equipment designed for easy use and accurate performance. It helps manufacturers compare material grades and project behavior during molding or extrusion. Accurate results and strong construction make it important for the plastic, automotive and packaging industries.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial #equipment

01:10 PM - Jun 10, 2025 (UTC)

Global Aluminum Extrusion Market – Industry Trends and Forecast to 2029 https://www.databridgemark...

05:16 AM - May 22, 2025 (UTC)

The Hidden Dangers of Processed Foods: Understanding Their Impact on Health and Society

In today's fast-paced world, processed foods have become an integral part of our daily lives. These convenient, readily available food products have transformed the way we eat, cook, and think about nutrition.

Food processing involves various technological and chemical processes designed to transform raw ingredients into the Processed Foods. These processes can include mechanical operations like grinding and milling, as well as more complex procedures such as extrusion, hydrogenation, and chemical preservation.

Processed Foods - https://www.coherentmarket...

In today's fast-paced world, processed foods have become an integral part of our daily lives. These convenient, readily available food products have transformed the way we eat, cook, and think about nutrition.

Food processing involves various technological and chemical processes designed to transform raw ingredients into the Processed Foods. These processes can include mechanical operations like grinding and milling, as well as more complex procedures such as extrusion, hydrogenation, and chemical preservation.

Processed Foods - https://www.coherentmarket...

09:47 AM - May 08, 2025 (UTC)

Sponsored by

OWT

5 months ago

Extrusion Sheet Market to Soar Owing to Lightweight Demand

Extrusion sheets are thermoplastic panels produced by forcing molten polymers—such as PVC, PP, PE, and PS—through a die to create uniform, high-strength sheets. These sheets offer excellent surface finish, consistent thickness, superior impact resistance, and design flexibility, making them ideal for applications in packaging, signage, automotive interiors, medical equipment, and building panels

As businesses seek sustainable packaging solutions and lightweight components to reduce carbon footprint, extrusion sheets address key industry challenges by enabling easier recyclability and reduced material consumption. E-commerce growth drives demand for protective packaging, while stringent hygiene standards in healthcare and food industries underpin the need for durable, easy-to-clean surfaces. In construction, extrusion sheets support energy-efficient wall and ceiling cladding systems.

Global Extrusion Sheet Market is estimated to be valued at USD 131.43 Bn in 2025 and is expected to reach USD 191.32 Bn by 2032, exhibiting a compound annual growth rate (CAGR) of 5.5% from 2025 to 2032.

Extrusion Sheet Market

https://www.coherentmarket...

Get More Insights On Extrusion Sheet Market

https://www.zupyak.com/p/4...

Extrusion sheets are thermoplastic panels produced by forcing molten polymers—such as PVC, PP, PE, and PS—through a die to create uniform, high-strength sheets. These sheets offer excellent surface finish, consistent thickness, superior impact resistance, and design flexibility, making them ideal for applications in packaging, signage, automotive interiors, medical equipment, and building panels

As businesses seek sustainable packaging solutions and lightweight components to reduce carbon footprint, extrusion sheets address key industry challenges by enabling easier recyclability and reduced material consumption. E-commerce growth drives demand for protective packaging, while stringent hygiene standards in healthcare and food industries underpin the need for durable, easy-to-clean surfaces. In construction, extrusion sheets support energy-efficient wall and ceiling cladding systems.

Global Extrusion Sheet Market is estimated to be valued at USD 131.43 Bn in 2025 and is expected to reach USD 191.32 Bn by 2032, exhibiting a compound annual growth rate (CAGR) of 5.5% from 2025 to 2032.

Extrusion Sheet Market

https://www.coherentmarket...

Get More Insights On Extrusion Sheet Market

https://www.zupyak.com/p/4...

05:34 AM - May 29, 2025 (UTC)

Optical Films Market Poised for Growth Owing to Display Demand

The Global Optical Films Market is estimated to be valued at US$ 32.23 Bn in 2025 and is expected to exhibit a CAGR of 8.7% over the forecast period 2025 to 2032.

Optical films are ultra-thin polymer sheets engineered to manipulate light by reflecting, diffusing, polarizing, or enhancing brightness on electronic displays and lighting systems. These films—including brightness enhancement films, anti-glare sheets, prism films, and reflective polarizers—boost panel efficiency, improve visual clarity, and reduce power consumption in devices ranging from smartphones and TVs to automotive HUDs and solar modules. Manufacturers leverage advanced coextrusion and surface-treatment processes to deliver films with precise optical properties, ensuring compatibility with emerging applications in flexible electronics and AR/VR headsets.

Get more insights on, Optical Films Market- https://www.patreon.com/po...

#CoherentMarketInsights #OpticalFilms #OpticalFilmsMarket #OpticalFilmsMarketInsights #PolarizingFilm #BacklightFilm

The Global Optical Films Market is estimated to be valued at US$ 32.23 Bn in 2025 and is expected to exhibit a CAGR of 8.7% over the forecast period 2025 to 2032.

Optical films are ultra-thin polymer sheets engineered to manipulate light by reflecting, diffusing, polarizing, or enhancing brightness on electronic displays and lighting systems. These films—including brightness enhancement films, anti-glare sheets, prism films, and reflective polarizers—boost panel efficiency, improve visual clarity, and reduce power consumption in devices ranging from smartphones and TVs to automotive HUDs and solar modules. Manufacturers leverage advanced coextrusion and surface-treatment processes to deliver films with precise optical properties, ensuring compatibility with emerging applications in flexible electronics and AR/VR headsets.

Get more insights on, Optical Films Market- https://www.patreon.com/po...

#CoherentMarketInsights #OpticalFilms #OpticalFilmsMarket #OpticalFilmsMarketInsights #PolarizingFilm #BacklightFilm

10:56 AM - Jun 05, 2025 (UTC)

Melt Flow Index Tester

Manufacturers can measure the flow rate and capability of materials by using a Melt Flow Index Tester, which analyzes the flow rate of thermoplastic polymers. It is important to maintain equality in quality control, extrusion and plastic manufacturing. By providing reliable material performance, this tool helps industries like consumer products, packaging and the automobile sector. It improves production productivity and product standards with its simple-to-use interface and accurate results. For reliable testing requirements, Perfect Group India offers dependable Melt Flow Index Testers.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #Instruments #industrial #equipment #technology

Manufacturers can measure the flow rate and capability of materials by using a Melt Flow Index Tester, which analyzes the flow rate of thermoplastic polymers. It is important to maintain equality in quality control, extrusion and plastic manufacturing. By providing reliable material performance, this tool helps industries like consumer products, packaging and the automobile sector. It improves production productivity and product standards with its simple-to-use interface and accurate results. For reliable testing requirements, Perfect Group India offers dependable Melt Flow Index Testers.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #Instruments #industrial #equipment #technology

11:29 AM - Jun 07, 2025 (UTC)

Melt Flow Index Tester

The flow rate of thermoplastic polymers under particular pressure and temperature conditions is measured by the Melt Flow Index Tester. It helps analyze material viscosity, quality, and processing suitability. The device offered by Perfect Group India delivers reliable and accurate testing for plastic manufacturers and research labs. This test is important for quality control, as it measures the polymer’s behavior during molding and extrusion processes, guarantee material performance in various industrial uses and product development.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial #equipment

The flow rate of thermoplastic polymers under particular pressure and temperature conditions is measured by the Melt Flow Index Tester. It helps analyze material viscosity, quality, and processing suitability. The device offered by Perfect Group India delivers reliable and accurate testing for plastic manufacturers and research labs. This test is important for quality control, as it measures the polymer’s behavior during molding and extrusion processes, guarantee material performance in various industrial uses and product development.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial #equipment

10:09 AM - Jun 11, 2025 (UTC)

Aluminium Extrusion Suppliers

https://aksharindustries.c...

Discover top-quality aluminium extrusion suppliers offering a wide range of profiles and products tailored for various industries. With a focus on durability and customisation, these suppliers ensure you get the perfect solutions for your construction and manufacturing needs.

#aluminiumextrusionsuppliers

https://aksharindustries.c...

Discover top-quality aluminium extrusion suppliers offering a wide range of profiles and products tailored for various industries. With a focus on durability and customisation, these suppliers ensure you get the perfect solutions for your construction and manufacturing needs.

#aluminiumextrusionsuppliers

08:01 AM - May 15, 2025 (UTC)

3D Printed Meat Market to Grow Fastest with Sustainable Protein Demand

The Global 3D Printed Meat Market is estimated to be valued at US$ 242.1 Mn in 2025 and is expected to exhibit a CAGR of 16.3% over the forecast period 2025 to 2032.

3D printed meat leverages advanced bioprinting technologies to fabricate structured, cell-based meat products layer by layer, mimicking the texture, flavor, and nutritional profile of conventional meat. Using cell-laden bio‐inks composed of animal stem cells and growth media, extrusion-based and laser-assisted bioprinting platforms can produce steaks, burgers, and seafood alternatives with precise control over fat distribution and muscle fiber alignment. As global population growth intensifies pressure on land and water resources, 3D printed meat addresses critical market drivers such as food security, animal welfare concerns, and fluctuating commodity prices. The industry also benefits from supportive regulatory frameworks and increasing investor interest, fueling market research and development in scalable bioreactors and high‐throughput printing systems.

Get more insights on, 3D Printed Meat Market- https://justpaste.me/PKOW6

#CoherentMarketInsights #3DPrintedMeat #3DPrintedMeatMarket #3DPrintedMeatMarketInsights #Beef #Poultry

The Global 3D Printed Meat Market is estimated to be valued at US$ 242.1 Mn in 2025 and is expected to exhibit a CAGR of 16.3% over the forecast period 2025 to 2032.

3D printed meat leverages advanced bioprinting technologies to fabricate structured, cell-based meat products layer by layer, mimicking the texture, flavor, and nutritional profile of conventional meat. Using cell-laden bio‐inks composed of animal stem cells and growth media, extrusion-based and laser-assisted bioprinting platforms can produce steaks, burgers, and seafood alternatives with precise control over fat distribution and muscle fiber alignment. As global population growth intensifies pressure on land and water resources, 3D printed meat addresses critical market drivers such as food security, animal welfare concerns, and fluctuating commodity prices. The industry also benefits from supportive regulatory frameworks and increasing investor interest, fueling market research and development in scalable bioreactors and high‐throughput printing systems.

Get more insights on, 3D Printed Meat Market- https://justpaste.me/PKOW6

#CoherentMarketInsights #3DPrintedMeat #3DPrintedMeatMarket #3DPrintedMeatMarketInsights #Beef #Poultry

3D Printed Meat Market to Soar Driven by Sustainability Demand

3D printed meat leverages advanced bioprinting technology to fabricate structured, cell-based protein products that mimic the texture, flavor, and nutritional ...

https://justpaste.me/PKOW6

12:47 PM - Jun 11, 2025 (UTC)

Melt Flow Index Tester

The Melt Flow Index Tester helps in measuring the flow of plastic when it melts, which is important to understanding the behavior of materials during manufacturing. It guarantees that polymers are suitable for extrusion or molding. Perfect Group India offers innovative products with trustworthy, quick results. It is widely used in the manufacturing of plastics and helps in waste reduction, quality control and improved productivity. For industries searching for the best results in material selection and final product strength, this tester is important.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial #equipment

The Melt Flow Index Tester helps in measuring the flow of plastic when it melts, which is important to understanding the behavior of materials during manufacturing. It guarantees that polymers are suitable for extrusion or molding. Perfect Group India offers innovative products with trustworthy, quick results. It is widely used in the manufacturing of plastics and helps in waste reduction, quality control and improved productivity. For industries searching for the best results in material selection and final product strength, this tester is important.

Visit us: https://www.perfectgroupin...

#perfectgroupindia #TestingTools #industrial #equipment

10:43 AM - May 27, 2025 (UTC)